2026 How to Use Polycarbonate Clear Plastic Sheet for Your Projects?

Polycarbonate clear plastic sheet is becoming increasingly popular in various industries. According to a recent report from Grand View Research, the global polycarbonate sheet market is projected to grow at a compound annual growth rate (CAGR) of 5.2% until 2028. This growth reflects the versatility and durability of polycarbonate materials, making them ideal for construction, automotive, and signage applications.

These sheets are lightweight yet strong, with the ability to withstand harsh weather conditions. They can be cut, drilled, and shaped easily, allowing for various project possibilities. Industry experts emphasize the importance of understanding the correct usage of polycarbonate clear plastic sheets. However, users must be cautious. Improper handling can lead to scratches or cracks, diminishing the material's visual appeal and functionality.

One key consideration is UV protection. While many polycarbonate sheets offer UV resistance, not all products provide the same level. Users should evaluate their needs carefully to avoid costly mistakes. Some sheets may yellow over time if not selected correctly. Hence, informed choices are vital for achieving optimal performance in projects.

Benefits of Using Polycarbonate Clear Plastic Sheets in Projects

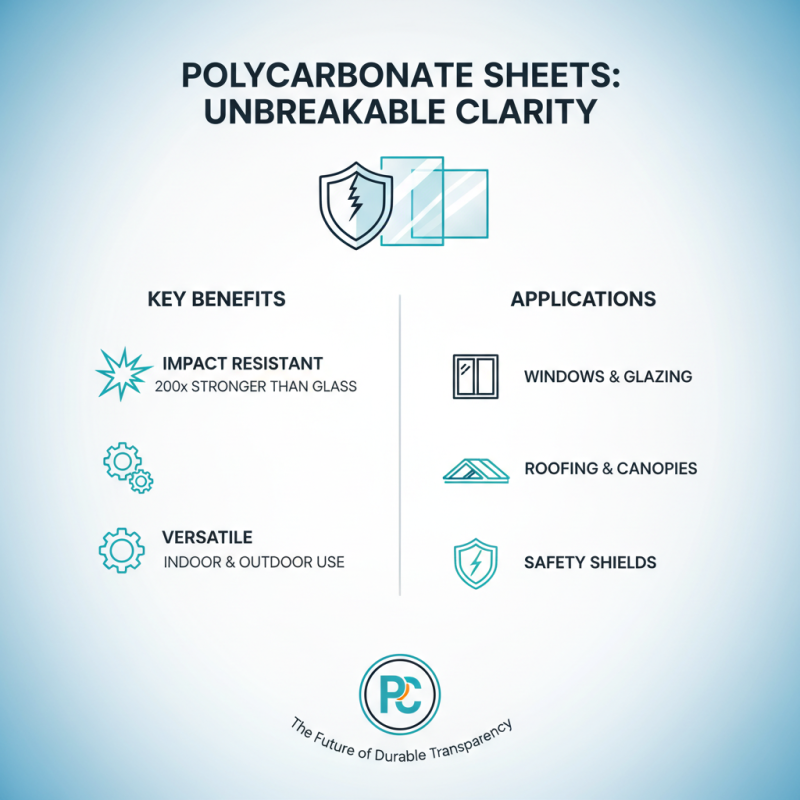

Polycarbonate clear plastic sheets are increasingly popular for a variety of projects. Their versatility is backed by industry reports that highlight their impact resistance, which is 200 times stronger than glass. This durability makes them an excellent choice for both indoor and outdoor applications.

One significant benefit is their lightweight nature. A standard polycarbonate sheet is less than half the weight of glass, facilitating easier handling during installation. Additionally, they provide excellent thermal insulation, often rated to minimize energy loss in buildings. According to studies, using polycarbonate can reduce energy costs by as much as 20% in some installations.

Tips for using polycarbonate sheets: Ensure you clean the surface properly before installation. This prevents debris from causing future issues. Also, consider using UV-protected sheets for projects exposed to direct sunlight. They offer long-term clarity and prevent yellowing, maintaining the aesthetic of your project.

Some users overlook the expansion properties of polycarbonate. When the material heats up, it can expand. Always allow for proper spacing in your design to accommodate this. This foresight can save you time and resources down the line. Polycarbonate sheets can be a smart choice when used thoughtfully, balancing strength, weight, and functionality.

Types of Projects Suitable for Polycarbonate Clear Plastic Sheets

Polycarbonate clear plastic sheets are versatile materials. They are perfect for various DIY projects. From home improvement to crafting, their durability is unmatched. You can use them for roofing, greenhouses, or even display cases. Their clarity allows light to pass through, which makes them suitable for many applications.

One popular use is in home renovations. You can create sleek room dividers or protective barriers. They resist impact well, which makes them ideal for areas with high foot traffic. In crafting, they can help produce stunning art pieces or custom signs. However, cutting them requires care. You may end up with jagged edges if you're not precise.

Building a greenhouse can be another exciting project. The sheets provide excellent insulation, trapping heat inside. Photosynthesis thrives under their transparent surface. Yet, not every project may turn out perfectly. Some sections might need adjustments or extra support. Being adaptable is crucial when working with this material. Remember, the journey can be just as rewarding as the finished project.

Step-by-Step Guide to Cutting Polycarbonate Clear Plastic Sheets

Cutting polycarbonate clear plastic sheets can seem daunting. However, with the right tools and techniques, it can be quite manageable. Start by gathering essential tools. You'll need a straight edge, a utility knife or circular saw, and safety goggles. Measure your sheet accurately. A small mistake can lead to wasted material.

It's important to score the sheet before breaking it. Use a straight edge to guide your knife. Make several passes to deepen the score line. This requires patience. Rushing can lead to uneven cuts. Once scored, you can snap the sheet along the line. Place your score facing up. Apply pressure gradually. It may take a few tries to get it right.

Tips: Always wear safety goggles. Polycarbonate can shatter, causing injury. Practice on scrap pieces before making your final cut. Also, ensure your work surface is stable. An unstable surface can lead to mistakes and frustrations. Don't hesitate to ask for help if you find it challenging. It’s okay to need assistance; learning is part of the process.

Best Practices for Installing Polycarbonate Clear Plastic Sheets

When installing polycarbonate clear plastic sheets, careful preparation is essential. Start by measuring the area where the sheet will be installed. Accuracy in these measurements will save you from making costly mistakes. Use a utility knife or saw for cutting, making sure to wear protective gear. Tread lightly; polycarbonate can be unpredictable if not handled with care.

Next, when it comes to fastening, opt for screws instead of nails. This allows for better adjustment and prevents potential cracking. Use washers to distribute pressure evenly on the sheet. Many people forget this step and end up with warped panels. It’s crucial to leave some space for expansion and contraction. A gap of about an eighth of an inch often suffices.

After installation, consider the cleaning process. It’s common to scratch the surface during this phase. Use only soft cloths and recommended cleaners. Harsh materials can ruin the clarity of polycarbonate. Even minor mistakes in maintenance can lead to bigger issues over time, diminishing the sheet's durability. Reflect on these practices. They can improve your outcomes significantly.

Maintenance Tips for Longevity of Polycarbonate Clear Plastic Sheets

Polycarbonate clear plastic sheets are known for their durability and versatility. To ensure their longevity, proper maintenance is crucial. Regular cleaning with mild soap and water can effectively remove dirt and grime. Avoid using abrasive materials, as they can scratch the surface. Reports indicate that scratches can reduce light transmission by up to 30%. This is significant for applications like greenhouses or skylights.

Inspecting your polycarbonate sheets periodically is essential. Look for signs of damage, such as cracks or yellowing. These issues may arise due to UV exposure over time. A study shows that untreated polycarbonate can lose 10-20% of its clarity within three years under constant UV exposure. Applying a UV protective coating can mitigate this effect.

Proper installation is also key. Ensure sheets are not subjected to extreme temperatures. Temperature fluctuations can cause expansion and contraction, potentially leading to warp. A well-structured framework can help prevent this. Polycarbonate sheets can last for many years if cared for properly, but neglect can lead to premature deterioration.

Related Posts

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

Top Benefits of Using Polycarbonate Sheets for Your Home and Projects

-

How to Choose the Right Solid Polycarbonate Sheet for Your Project

-

How to Choose the Right Polycarbonate Multiwall Sheet for Your Project?

-

Top 10 Benefits of ABS Plastic You Need to Know in 2023

-

The Ultimate Guide to Polycarbonate Multiwall Sheets Benefits and Uses