2026 Top Polycarbonate Suppliers for Your Essential Needs?

In the dynamic world of manufacturing and construction, the role of polycarbonate suppliers cannot be overlooked. These suppliers are vital in providing high-quality materials essential for durability and safety. According to industry expert John Smith, “Finding the right polycarbonate suppliers can make or break your project.” This insight highlights the importance of choosing reliable partners in this sector.

Navigating the landscape of polycarbonate suppliers can be challenging. With numerous options available, identifying the best fit is crucial. Suppliers vary in their offerings, quality control, and customer service. Poor choices can lead to delays or subpar results. Striving for excellence in material procurement is essential for successful project outcomes.

Industry challenges often arise, making clear communication and trust essential elements in supplier relationships. Finding suppliers that align with project needs requires due diligence. Reflecting on previous partnerships may reveal areas for improvement. In an ever-evolving market, staying informed about leading polycarbonate suppliers can provide a competitive edge.

Overview of Polycarbonate and Its Applications

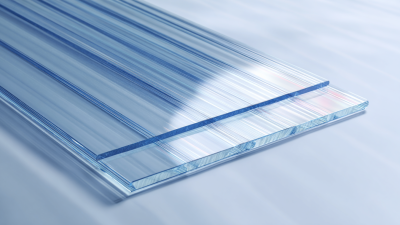

Polycarbonate is a versatile thermoplastic known for its excellent impact resistance and clarity. This material is lightweight yet strong, making it ideal for a wide range of applications. It is commonly used in eyewear lenses, electronic components, and safety glasses. The ability to withstand high temperatures adds to its appeal, especially in industrial settings.

In construction, polycarbonate panels offer natural light transmission while providing insulation. These panels are often used in greenhouses and skylights. In automotive applications, polycarbonate is used for headlight covers, providing durability and transparency. Despite its many advantages, polycarbonate can be marred by scratches if not treated properly. This is a critical point for various applications, where clarity is vital.

Some might overlook the environmental impact of polycarbonate production. While it is recyclable, many facilities do not offer proper recycling options. This can lead to significant waste issues. Industry professionals often find themselves pondering how to balance the benefits of polycarbonate with sustainability. The demand for innovation in recycling methods reflects this ongoing challenge.

Criteria for Selecting Top Polycarbonate Suppliers

When selecting top polycarbonate suppliers, consider several critical criteria. Quality assurance is paramount. High-quality polycarbonate provides durability and impact resistance. Reports indicate that the global polycarbonate market is anticipated to grow at a CAGR of about 5.7% from 2021 to 2026. Choose suppliers with robust quality control processes.

Delivery timelines are another factor. Suppliers must meet your production schedule. Late deliveries can disrupt operations. Look for companies with a proven record of on-time delivery. However, be prepared for potential delays due to unforeseen circumstances. Flexibility and communication with suppliers can mitigate impacts.

Price is essential too. Analyze pricing structures carefully. The lowest price is not always the best option. Assess the overall value offered, considering factors like quality and service. A balance between cost and service quality is vital. Don't hesitate to negotiate terms that work for you.

Tips: Build a relationship with your supplier. This fosters better communication and trust. Regular feedback can guide improvements. Always perform a risk assessment with your chosen supplier. This can help in identifying potential issues before they arise.

List of Leading Polycarbonate Suppliers in 2026

In 2026, the demand for polycarbonate materials continues to rise. Many industries rely on this versatile plastic for its strength, durability, and thermal resistance. It is especially popular in sectors like automotive, construction, and electronics. However, finding the right supplier can be challenging.

Several polycarbonate suppliers stand out this year. They offer a range of products and services. Some focus on innovative processing techniques. Others emphasize sustainability in their manufacturing. Quality is crucial, yet not all suppliers meet industry standards. Potential buyers need to do their research to avoid poor choices.

While many suppliers promise high-quality materials, ensuring timely delivery is often a concern. Some customers report delays that impact their projects. It's vital to weigh the pros and cons of each supplier. Transparency in communication is crucial. It's best to engage with suppliers who provide clear information on their processes and timelines.

2026 Polycarbonate Supplier Market Share

This chart represents the estimated market share distribution among various sectors of the polycarbonate supply industry in 2026. The data reflects industry trends and demands, indicating where significant growth and supply needs are observed.

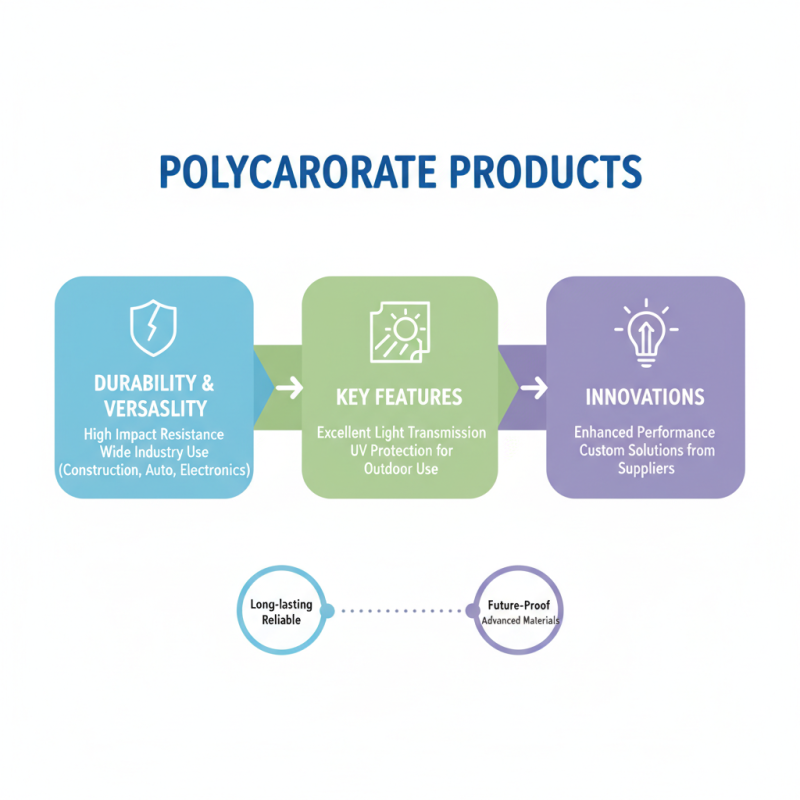

Key Features and Innovations in Polycarbonate Products

Polycarbonate products are renowned for their remarkable durability and versatility. They are widely used in industries like construction, automotive, and electronics. Key features include high impact resistance and excellent light transmission. Many suppliers offer unique innovations that enhance the performance of polycarbonate materials. For example, some products feature UV protection, preventing degradation from sunlight exposure. This is essential for outdoor applications.

Temperature regulation is another vital aspect of polycarbonate. Some materials come with enhanced thermal insulation properties. This can reduce energy costs and improve comfort in buildings. However, not all suppliers meet these standards. It’s crucial to evaluate the thermal performance data. Some options may not deliver as promised, leading to unexpected issues.

Additionally, customization options are becoming more common. Coatings and textures can enhance both functionality and aesthetics. This trend allows for more creative applications. Nonetheless, buyers should remain cautious. Over-promising features can lead to disappointment. Thorough research on specific supplier offerings is necessary. This helps in making informed decisions that align with essential needs.

Market Trends Shaping the Future of Polycarbonate Manufacturing

The polycarbonate market is evolving rapidly. Manufacturers are adapting to new technologies and trends. Sustainability is becoming a key focus. There is a growing demand for recycled polycarbonate materials. This shift offers exciting opportunities for suppliers.

Tips: Look for suppliers who prioritize eco-friendly practices. Their commitment can impact your product's sustainability.

Innovation is also shaping the future. Advanced production techniques are emerging. These methods enhance product quality while reducing costs. Yet, there are challenges. Not all manufacturers can keep up with these changes. Some still rely on outdated processes.

Tips: Regularly evaluate your suppliers' capabilities. Choose those who invest in modern technology.

Market trends indicate a focus on customization. Customers want tailored solutions for their specific needs. This requires flexibility in manufacturing. However, some companies may struggle to meet these demands. A balance between standardization and customization is crucial for success.

Related Posts

-

Top 7 Benefits of Using Opaque Polycarbonate in Modern Architectural Design

-

10 Essential Tips for Choosing the Right PVC Sheets for Your Projects

-

How to Use Opaque Plastic Sheeting for Effective Light Blockage and Privacy

-

Top Solid Plastic Sheets Uses Benefits and Buying Guide

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

Why is Clear Plastic the Best Choice for Your Next Project