Top 10 Benefits of ABS Plastic You Need to Know in 2023

In the ever-evolving landscape of materials used in manufacturing and product development, ABS plastic has emerged as a frontrunner due to its remarkable properties and versatility. As we step into 2023, understanding the advantages of ABS plastic is essential for industries ranging from automotive to consumer goods. This engineering thermoplastic is renowned for its durability, strength, and resistance to impact, making it an ideal choice for a wide array of applications.

Whether you're a designer, engineer, or manufacturer, recognizing the benefits of ABS plastic can enhance your products and streamline your processes. From its lightweight nature to its ability to be easily molded and colored, ABS plastic offers unparalleled flexibility in design and function. Additionally, its resilience in various environmental conditions ensures longevity and reliability, making it a preferred material for both indoor and outdoor applications. In this article, we will explore the top 10 benefits of ABS plastic that you need to know in 2023, highlighting why it remains a key material in modern manufacturing.

Understanding ABS Plastic: A Comprehensive Overview

ABS (Acrylonitrile Butadiene Styrene) plastic, a thermoplastic polymer, has gained significant attention in various industries due to its outstanding properties. Widely used in products ranging from automotive components to consumer electronics, ABS is renowned for its excellent impact resistance and toughness. According to a report by Research and Markets, the global ABS market is expected to grow significantly, reaching an estimated value of $29 billion by 2027, highlighting its increasing importance and applications.

The versatility of ABS plastic lies in its ability to be easily molded and processed, making it ideal for intricate designs and applications. This adaptability is underscored by its performance across a range of temperatures, allowing it to maintain structural integrity and flexibility under various conditions. A study from MarketsandMarkets indicates that the automotive sector alone accounts for over 30% of ABS consumption, driven by the need for lightweight, durable materials that enhance vehicle performance and fuel efficiency.

In addition to its mechanical properties, ABS plastic is also recognized for its recyclability and environmental benefits. The growing emphasis on sustainable practices has led to innovations in ABS recycling processes, allowing manufacturers to reduce waste and minimize their carbon footprint. As industries continue to shift toward eco-friendly materials, the demand for ABS plastic is likely to increase, reinforcing its status as a key player in modern manufacturing and product design.

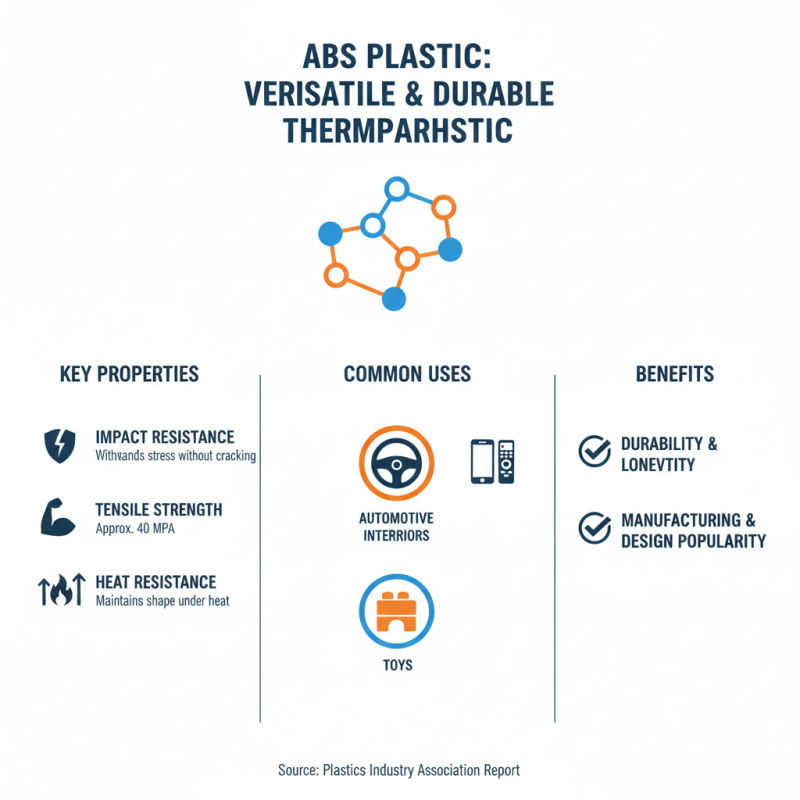

Key Properties and Characteristics of ABS Plastic

ABS plastic, or Acrylonitrile Butadiene Styrene, is a versatile thermoplastic widely used in various industries due to its remarkable properties. Known for its excellent impact resistance, ABS can withstand significant stress without cracking, making it ideal for applications that require durability. According to a report by the Plastics Industry Association, ABS plastic has a tensile strength of approximately 40 MPa, which is essential for products such as automotive interiors, consumer electronics, and toys. Its ability to maintain shape and resist deformation under heat provides another significant advantage, contributing to its popularity in manufacturing and design.

Additionally, ABS plastic exhibits outstanding chemical resistance, ensuring that it is stable in the presence of many acids and bases. This characteristic is highlighted in the Polymeric Materials: Science and Engineering journal, which states that ABS maintains structural integrity from -20°C to 80°C, making it suitable for both hot and cold environments. Moreover, its ease of processing through injection molding and extrusion techniques allows for efficient and cost-effective production methods.

**Tips:** When working with ABS, it’s essential to consider proper ventilation during the processing stage, as the material can release fumes. Always ensure that your working environment is equipped with the necessary safety equipment. For those considering 3D printing with ABS, maintaining a stable temperature in the printing area can help prevent warping and ensure a smooth finish on the final product.

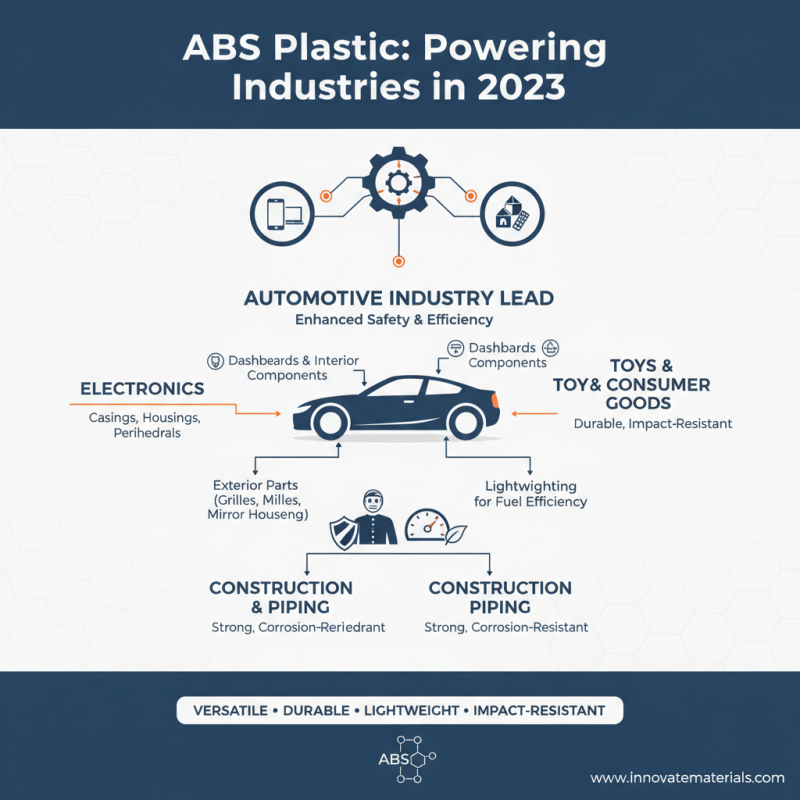

Top Applications and Industries Utilizing ABS Plastic

ABS plastic, known for its versatility and durability, has found widespread applications across various industries in 2023. One of the most significant sectors utilizing ABS is the automotive industry, where it is used for manufacturing dashboards, interior components, and even some exterior parts. The material's strength-to-weight ratio and resistance to impacts make it an ideal choice for enhancing vehicle safety and efficiency while reducing overall weight.

In the realm of consumer electronics, ABS plastic is prevalent due to its excellent insulation properties and ability to withstand high temperatures. It is commonly used in the production of housings for devices such as smartphones, laptops, and gaming consoles. Additionally, the toy industry relies heavily on ABS for its robust and colorful properties, making it a favorite for designing toys that are safe, durable, and engaging for children. The combination of ease of molding and the ability to add vibrant colors ensures that manufacturers can meet various design requirements effectively.

Environmental Impact and Sustainability of ABS Plastic

ABS plastic, or Acrylonitrile Butadiene Styrene, is known for its impactful role in sustainability and environmental considerations. Its production process is increasingly focusing on reducing greenhouse gas emissions, making it a preferable choice for manufacturers aiming for eco-friendly practices. Furthermore, ABS is fully recyclable, which not only lessens its environmental footprint but also allows for its repeated use in various applications. This characteristic encourages a circular economy, where materials are reused, minimizing waste and resource consumption.

In addition, ABS plastic can contribute to energy efficiency. Its lightweight nature reduces the energy required during transportation and installation, leading to lower overall carbon emissions. Moreover, advancements in recycling technologies are enhancing the ability to reclaim and repurpose ABS materials, ensuring that valuable resources are conserved. These developments make ABS plastic not only a practical choice for various industries but also a viable option for promoting environmental sustainability. By prioritizing materials like ABS, companies can work towards more responsible production methods while still meeting consumer demands for durable and versatile products.

Cost-Effectiveness and Durability of ABS Plastic Products

ABS plastic, known for its impressive cost-effectiveness, has become a popular choice for various applications in 2023. Its relatively low production cost allows manufacturers to create high-quality products without inflating prices. This feature makes ABS an attractive option for businesses looking to maximize profit margins while still delivering reliable products to consumers. The economic benefits extend to consumers as well, as they can access durable products without breaking the bank.

In addition to its affordability, ABS plastic is renowned for its durability. This material boasts excellent resistance to impact and stress, which means products made from ABS can withstand daily wear and tear. Whether used in automotive parts, consumer electronics, or household items, ABS plastic ensures longevity, reducing the need for frequent replacements. This durability not only contributes to savings over time but also promotes sustainability by minimizing waste. As a result, the integration of ABS plastic into various industries reflects a commitment to both economic efficiency and environmental responsibility.

Top 10 Benefits of ABS Plastic in 2023

This chart illustrates the top 10 benefits of ABS plastic in 2023, showcasing its cost-effectiveness and durability, alongside other key advantages like lightweight, impact resistance, and versatility.

Related Posts

-

Top 10 Benefits of ABS Material in Manufacturing for Enhanced Durability and Cost Efficiency

-

2025 Top 10 Clear Plastic Innovations Transforming Everyday Life

-

Top 10 Benefits of Using Transparent Sheets for Your DIY Projects

-

Top 10 Benefits of Using Coloured Sheets for Your Home and Office

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

How to Use Opaque Plastic Sheeting for Effective Light Blockage and Privacy