Top 10 Tips for Choosing the Right Plastic Roll for Your Needs?

Choosing the right plastic roll can be overwhelming. With so many options available, it's crucial to understand your specific needs. John Smith, a leading expert in the plastic roll industry, once said, “The perfect plastic roll depends on its application and the unique demands of your project.” His insight emphasizes the importance of tailored selections.

When selecting a plastic roll, consider factors such as thickness, width, and durability. Different projects require different materials. For instance, food packaging and construction films have unique requirements. A mismatch can lead to waste or, worse, product failure. You need to think critically about your specific use cases.

Even with careful consideration, mistakes can happen. It's easy to overlook details like chemical resistance or UV stability. Reflecting on past choices can help in making better future decisions. In the end, the right plastic roll can enhance efficiency and ensure quality in your work.

Understand Your Specific Needs and Applications for Plastic Rolls

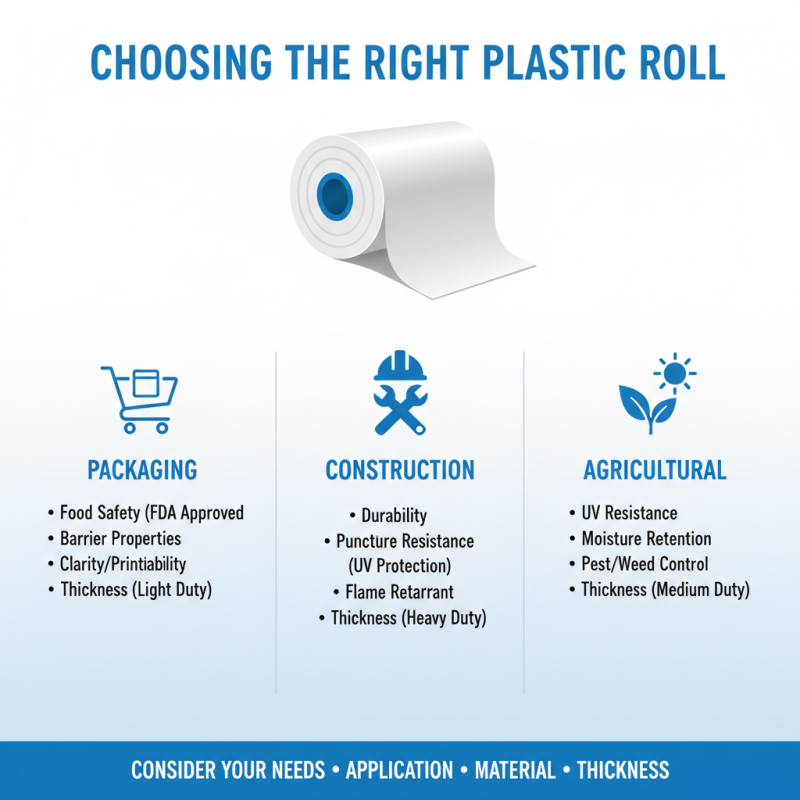

When selecting the right plastic roll, it’s crucial to understand your specific needs. Consider the application. Are you using it for packaging, construction, or agricultural purposes? Each use requires different materials and thicknesses. A roll intended for outdoor use needs UV protection. For food packaging, safety is a top priority.

Think about size too. Measuring your workspace or storage area can help avoid problems. Many people underestimate the space required. This can lead to inefficient use of materials. Reflect on your expected volume. Will you need a larger roll for bulk use, or a smaller option for occasional tasks? A wrong choice might waste resources and time.

Don’t forget about durability. Some plastics are more robust than others. Choosing a type that can withstand wear and tear is essential. Evaluate your environment as well. High humidity might affect certain plastics. Testing different materials can be beneficial. This helps you find the right balance between cost and quality. Be prepared to adjust your choices as needed.

Evaluate Different Types of Plastic Materials Available on the Market

When considering plastic rolls, evaluating different types of plastic materials is essential. A recent industry report indicates that polyethylene (PE) accounts for over 30% of global plastic production. PE is lightweight, flexible, and moisture-resistant, making it ideal for packaging. However, its non-biodegradable nature raises environmental concerns. Many manufacturers focus on sustainability, which sometimes compromises durability.

Polypropylene (PP) is another popular option, known for its heat resistance and strength. It makes excellent packaging materials, yet sourcing high-quality PP can be challenging. According to market analyses, only about 40% of companies prioritize quality over cost. This leads to potential long-term issues with product integrity.

PVC, or polyvinyl chloride, offers rigidity and weather resistance. However, its production often involves toxic chemicals. The market is divided—users must weigh performance against environmental impact. Plastic type choices must reflect specific needs while keeping sustainability in mind. Not every option is suitable for all applications, raising questions about long-term usability and disposal.

Top 10 Tips for Choosing the Right Plastic Roll for Your Needs

Consider the Thickness and Durability Required for Your Project

When selecting a plastic roll, thickness and durability are critical factors. You need to know the specific requirements of your project. Thicker rolls generally offer greater strength and resistance to wear. However, they may be heavier and harder to work with. If you’re unsure, consider the environment where the plastic will be used. For example, outdoor projects may require thicker rolls to withstand UV exposure.

Choosing the right durability level requires careful thought. Some projects need materials that can endure harsh chemicals or extreme temperatures. For simpler tasks, a thinner roll may suffice. However, if you underestimate the demands of your project, you might face challenges later on. Weak materials could lead to tears or leaks, causing frustration. Always think ahead and consider the long-term impact on your project.

Evaluate your options thoroughly. Balancing thickness and durability can be tricky. It’s essential to match these features to your specific needs. Take your time to compare different types. Sometimes, it might be beneficial to consult with others who have experience. Engaging in discussions can bring clarity and help avoid common pitfalls in your decision-making process.

Top 10 Tips for Choosing the Right Plastic Roll for Your Needs

| Tip Number | Consideration | Description |

|---|---|---|

| 1 | Thickness | Select the appropriate thickness for strength and protection. |

| 2 | Durability | Ensure the plastic roll can withstand environmental conditions. |

| 3 | Compatibility | Check if the plastic is suitable for the intended application. |

| 4 | Transparency | Decide whether visibility is crucial for your project. |

| 5 | UV Resistance | Consider if the plastic needs UV protection for outdoor use. |

| 6 | Chemical Resistance | Ensure the material can resist chemicals it may encounter. |

| 7 | Cost | Find a balance between cost and quality for your budget. |

| 8 | Eco-Friendliness | Look for sustainable options to reduce environmental impact. |

| 9 | Width and Length | Select the sizes that best fit your project requirements. |

| 10 | Supplier Reputation | Choose reputable suppliers for quality assurance and service. |

Analyze Cost Factors and Budget Constraints for Plastic Rolls

When choosing a plastic roll, cost factors matter significantly. Consider your budget before purchasing. Different types of plastic rolls come with various price tags. Calculate costs based on size and thickness. A thicker roll may be more durable but could strain your budget.

Look for bulk discounts if you need large quantities. This can save you money long term. Don’t forget shipping costs; they can add up quickly. Sometimes, free shipping thresholds can look appealing but may not suit small orders.

Evaluate specific needs. Are you using the plastic for packaging or as a protective layer? Different applications may require different types of plastic. A heavy-duty roll is essential for industrial use. However, lighter rolls may suffice for personal projects. Prioritize your requirements to avoid overspending on unwanted features.

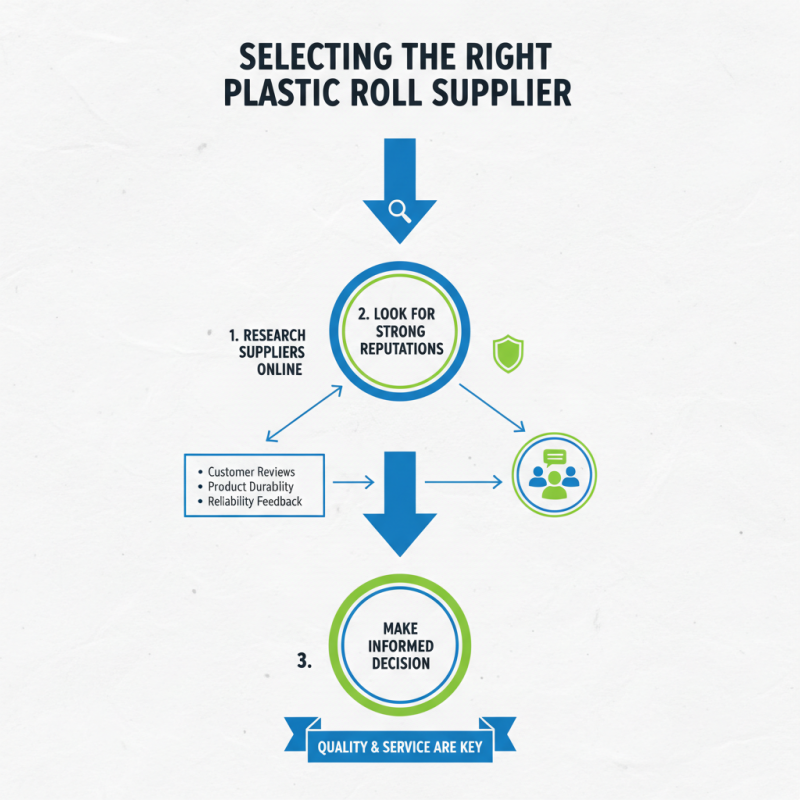

Research Suppliers and Compare Quality and Service Options

When selecting the right plastic roll, researching suppliers is crucial. A quick online search can yield numerous options. Look for suppliers with strong reputations. Customer reviews often provide insights into quality and service. Pay attention to feedback on product durability and reliability.

Comparing quality and service options is essential. Request samples to evaluate the plastic's thickness and flexibility. Understand the supplier's delivery times and customer support structure. It's important to know how quickly you can get replacements if needed. A supplier's responsiveness can be very telling.

Sometimes, the cheapest option doesn't mean the best value. Low prices can correlate with poor quality. Reflect on your long-term needs versus immediate savings. A more reliable supplier may save you money in the long run. Be prepared to ask questions and clarify details.

Related Posts

-

Top Benefits of Using Coloured Plastic Sheets in 2025 for Your Projects

-

2025 Top 10 Clear Plastic Innovations Transforming Everyday Life

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

How to Choose Transparent Polycarbonate for Your Projects?

-

How to Choose the Best Plastic Products for Your Needs and Sustainability

-

What is a Plastic Board and Its Best Uses?