What is a Solid Polycarbonate Sheet and Its Applications?

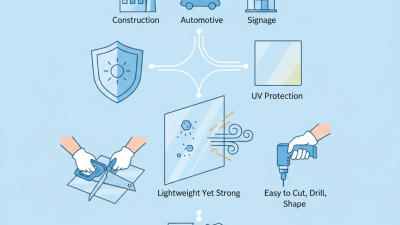

Solid polycarbonate sheet is a versatile material known for its strength and clarity. According to industry reports, the global polycarbonate sheets market is expected to grow at a compound annual growth rate (CAGR) of approximately 5% from 2022 to 2027. This growth is driven by diverse applications in construction, automotive, and electronics sectors.

Through its impact resistance and lightweight nature, solid polycarbonate sheet stands out compared to glass and acrylic. For instance, it is 200 times stronger than glass. This makes it ideal for safety applications where resilience is key. Furthermore, they offer excellent UV protection, contributing to energy efficiency in buildings.

However, it is essential to consider the environmental impact of polycarbonate sheets. The production process can generate significant waste. Recycling options are limited, raising questions about sustainability. These factors highlight the need for responsible usage and advancements in eco-friendly materials. Overall, solid polycarbonate sheets continue to play a crucial role in various industries, balancing innovation with environmental concerns.

What is Solid Polycarbonate Sheet?

Solid polycarbonate sheets are versatile materials known for their remarkable strength and clarity. These sheets are manufactured from polycarbonate resin, a type of thermoplastic that offers durability. According to a report by MarketsandMarkets, the global polycarbonate market size is projected to grow significantly due to rising demand in various sectors.

The composition of solid polycarbonate sheets provides excellent impact resistance, making them ideal for applications like safety glasses, greenhouses, and protective barriers. Their ability to withstand harsh weather conditions is crucial for outdoor applications. It is noteworthy that these sheets can block harmful UV rays, yet they are lightweight, which eases installation processes.

However, there are some challenges associated with solid polycarbonate sheets. While they are resistant to cracking, they can scratch easily. This can impact their aesthetics over time. Some manufacturers have tried to address this with special coatings, but the effectiveness varies widely. Regular maintenance is crucial for preserving their clarity and performance. Users should consider these factors when choosing solid polycarbonate sheets for specific applications.

Properties and Characteristics of Solid Polycarbonate Sheets

Solid polycarbonate sheets are known for their impressive strength and durability. These sheets are lightweight yet highly impact-resistant, making them suitable for various applications. They can withstand harsh weather conditions, which is crucial for outdoor use. Their optical clarity is another feature, allowing for excellent light transmission. This makes them ideal for applications like skylights and greenhouses.

In addition to strength, polycarbonate sheets have good thermal insulation properties. They can help regulate temperatures in buildings, which can save energy costs. Their easy workability allows for various shapes and sizes, appealing to designers and architects. However, the sheets can scratch easily, requiring careful handling.

The versatility of solid polycarbonate sheets extends to industries like safety and automotive. They can replace glass in security applications, providing a safer alternative. While they offer many advantages, users should consider their limitations, such as UV degradation over time. This raises the question: how can we enhance that aspect for longer-lasting use?

Common Applications of Solid Polycarbonate Sheets

Solid polycarbonate sheets are versatile materials known for their strength and durability. They can withstand high impact and resist UV radiation. This makes them ideal for various applications. One common use is in commercial greenhouses. The sheets allow sunlight to penetrate while providing insulation. This helps plants thrive, even in colder climates.

Another popular application is in safety barriers. Solid polycarbonate sheets are lightweight and unbreakable. They can be used in places like shopping malls and airports. These barriers protect people while maintaining visibility. Additionally, these sheets are often used in signage and displays. Their clarity and weather resistance make them perfect for outdoor use. From roofing systems to face shields, the possibilities seem endless but may sometimes feel overwhelming.

In construction, solid polycarbonate sheets are utilized for skylights and windows. They are energy-efficient and can save on heating costs. However, installation can be tricky. Ensuring proper sealing is essential to avoid leaks. The sheets can also scratch over time, so maintenance is important. Despite their numerous benefits, reflection on their long-term sustainability in various applications is necessary.

Advantages of Using Solid Polycarbonate Sheets

Solid polycarbonate sheets are known for their versatility and strength. They are much more durable than glass and can resist impact up to 200 times stronger. This unique property makes them ideal for various applications, such as skylights, signs, and safety shields. According to a report by the Global Market Insights, the polycarbonate sheet market is expected to surpass $3 billion by 2026, driven by their rising demand in construction and automotive industries.

One significant advantage of using solid polycarbonate sheets is their lightweight nature. Weighing only half as much as glass, they are easier to handle and install. In addition, polycarbonate sheets offer excellent thermal insulation, reducing energy consumption in buildings. Industry data suggests that using these sheets can lead to a 25% decrease in heating expenses for commercial structures. Moreover, their high resistance to UV rays protects underlying materials from degradation, enhancing longevity significantly.

However, it's important to note that while polycarbonate sheets are durable, they can scratch easily. Proper care is essential to maintain their clarity over time. Many users find that insufficient cleaning methods lead to unsatisfactory results. Balancing durability and maintenance remains a point of reflection for prospective users.

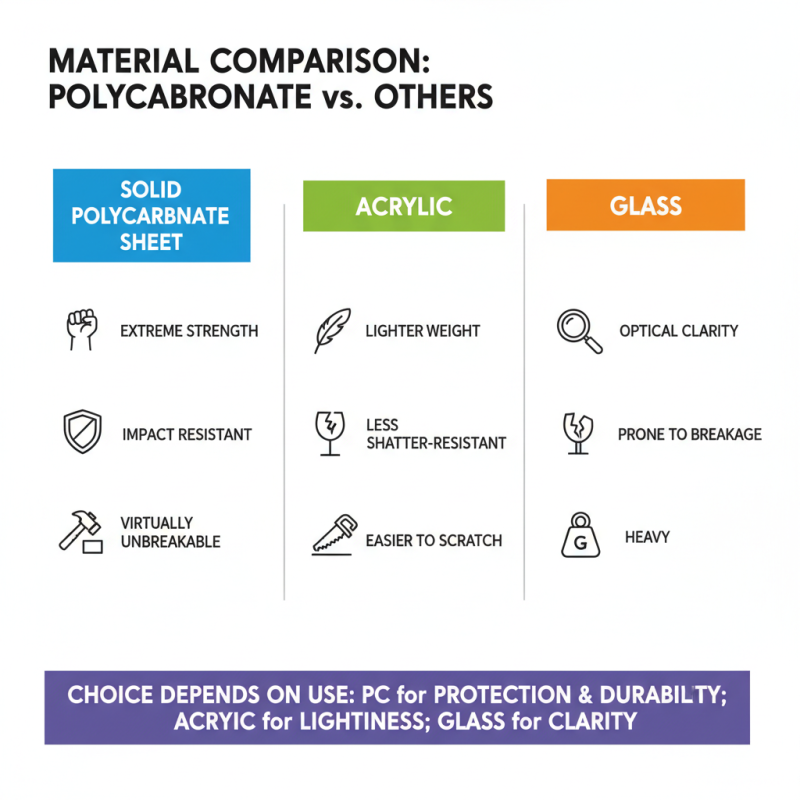

Comparison with Other Materials in Similar Applications

When comparing solid polycarbonate sheets to other materials, several aspects stand out. Polycarbonate is known for its strength and durability. It can withstand heavy impacts, making it ideal for protective applications. Acrylic is often lighter but less shatter-resistant. Glass provides excellent clarity but is prone to breakage. These differences can influence material choice depending on the intended use.

Cost is another factor to consider. Polycarbonate sheets may be more expensive than acrylic. However, their longevity can justify the investment. For certain applications, such as security glazing or safety shields, the extra expense might be worth it. On the flip side, for projects that need lightweight but clear materials, acrylic could be more appropriate.

Some industries might still lean towards glass, despite its fragility. This choice often stems from aesthetic preferences rather than practical ones. Additionally, polycarbonate doesn’t have the same level of UV resistance as specialized glass. This can lead to degradation over time if not properly treated. Each material has its strengths and weaknesses. It’s essential to weigh these carefully before making a decision.

Related Posts

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

Top Benefits of Using Polycarbonate Sheets for Your Home and Projects

-

How to Choose the Right Solid Polycarbonate Sheet for Your Project

-

2026 Top Polycarbonate Suppliers for Your Essential Needs?

-

How to Choose the Right Polycarbonate Panels for Your Project?

-

2026 How to Use Polycarbonate Clear Plastic Sheet for Your Projects?