Top Solid Plastic Sheets Uses Benefits and Buying Guide

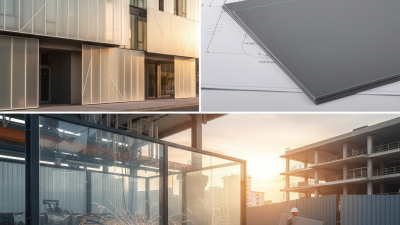

Solid plastic sheets have gained immense popularity in various industries due to their versatility, durability, and ease of use. From construction and manufacturing to artistic endeavors, these sheets provide a reliable solution for a myriad of applications. Their ability to withstand various environmental conditions, coupled with a range of aesthetic options, makes solid plastic sheets a preferred choice for both functional and decorative projects.

In this guide, we will explore the numerous benefits of solid plastic sheets, such as their lightweight nature, resistance to moisture and chemicals, and ease of fabrication. We will also delve into common uses across different sectors, demonstrating how these sheets can be adapted to meet specific needs, whether it's creating signage, protective barriers, or custom furniture. Understanding the advantages and applications of solid plastic sheets will empower you to make informed purchasing decisions that align with your project goals.

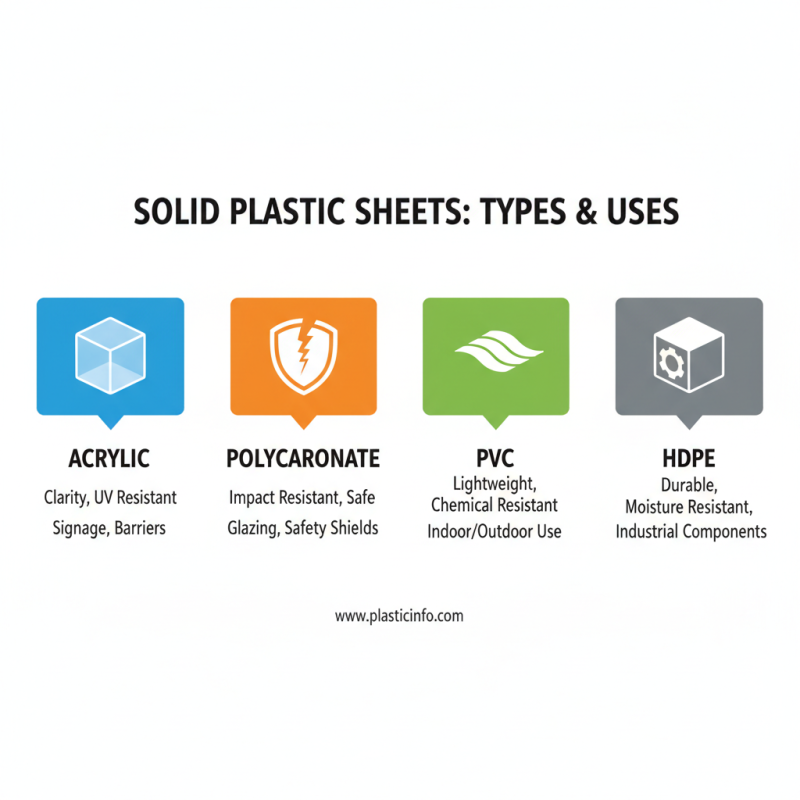

Top Solid Plastic Sheets: An Overview of Types and Features

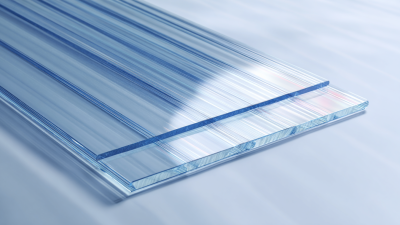

Solid plastic sheets are versatile materials that come in various types, each tailored to specific applications. Common types include acrylic, polycarbonate, PVC, and HDPE, among others. Acrylic sheets are renowned for their clarity and UV resistance, making them ideal for applications such as signage and protective barriers. Polycarbonate sheets offer superior impact resistance and are often used in environments where safety is a priority, such as in glazing and safety shields. PVC sheets are lightweight and chemically resistant, making them suitable for indoor and outdoor use, while HDPE is noted for its durability and resistance to moisture, often utilized in packaging and industrial components.

The features of these solid plastic sheets contribute significantly to their functionality. For instance, many sheets can be easily fabricated, allowing for custom shapes and sizes without losing structural integrity. They are also available in various thicknesses, providing flexibility for different levels of strength and insulation needs. Additionally, solid plastic sheets can come in a range of colors and finishes, enabling aesthetic integration into designs while offering practical benefits like thermal insulation, sound dampening, and ease of maintenance. As industries continue to innovate, the applications and advantages of solid plastic sheets are likely to expand further, making them an indispensable resource across various fields.

Key Advantages of Using Solid Plastic Sheets in Various Applications

Solid plastic sheets have gained considerable traction across various industries due to their distinctive advantages. According to a report by Smithers Pira, the global market for plastic sheets is expected to reach $3.5 billion by 2025, reflecting a growing preference for lightweight, durable materials. These sheets are known for their versatility, as they can be employed in applications ranging from signage and construction to packaging and furniture manufacturing. The superior impact resistance and weatherability make solid plastic sheets an ideal choice for outdoor and high-traffic environments, where traditional materials may falter.

Another significant benefit is the ease of fabrication and maintenance. Solid plastic sheets can be easily cut, shaped, and fabricated to meet specific design requirements, offering substantial flexibility in various projects. A study published by GlobalData highlights that over 50% of manufacturers prefer solid plastic sheets due to their cost-effectiveness and low maintenance requirements, resulting in reduced operational costs over time. Additionally, these sheets are often made from recyclable materials, aligning with sustainability goals and minimizing environmental impact, making them a responsible choice for modern applications.

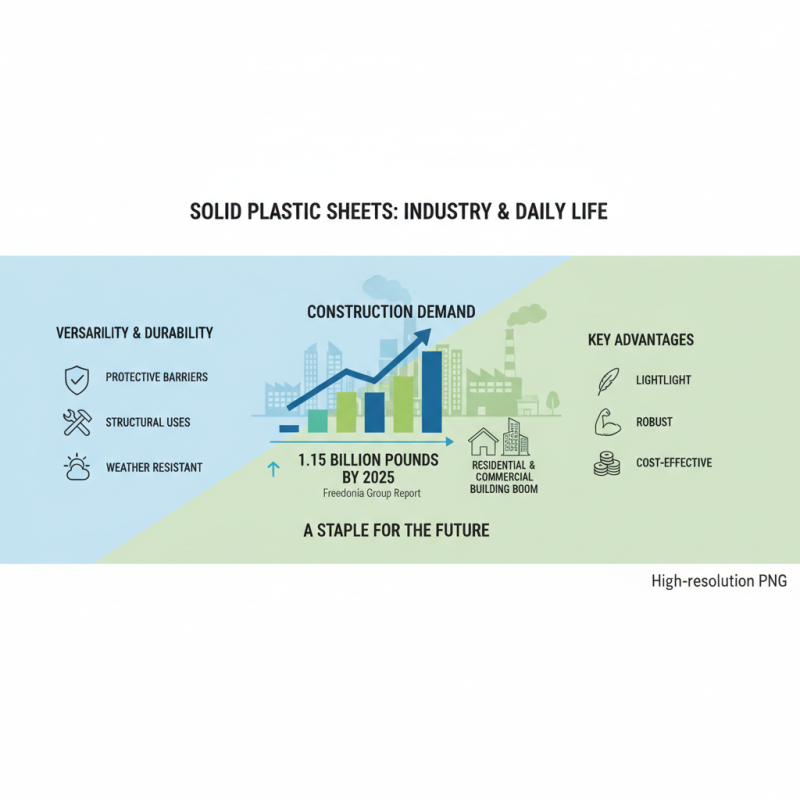

Common Uses of Solid Plastic Sheets in Industries and Daily Life

Solid plastic sheets are increasingly becoming a staple across various industries and daily life due to their versatility, durability, and cost-effectiveness. In construction, for instance, they are widely utilized for temporary protective barriers and project signage. According to a report from the Freedonia Group, the demand for plastic sheets in construction applications is projected to reach 1.15 billion pounds by 2025, driven by an increase in residential and commercial building activities. Their lightweight yet robust nature makes them ideal for various structural applications, while their resistance to weather elements ensures longevity.

In the manufacturing sector, solid plastic sheets serve critical roles in signage, displays, and packaging. Industries such as retail and hospitality rely on these materials for their vibrant colors and ability to be easily fabricated into various shapes. A study by IBISWorld indicates that the plastic manufacturing industry generates approximately $35 billion annually, with solid plastic sheets constituting a significant portion of this revenue. By using lightweight yet durable materials, businesses can enhance their product presentation while reducing shipping costs and minimizing environmental impact through recyclability.

Additionally, in everyday life, solid plastic sheets are utilized in DIY projects, home improvement tasks, and artistic endeavors. Their ease of use and availability in various thicknesses make them appealing to homeowners and hobbyists. Research shows that DIY home improvement projects have surged by nearly 20% in recent years, indicating a growing market for affordable and practical materials like solid plastic sheets that offer innovative solutions for everyday challenges.

Buying Guide: Factors to Consider When Choosing Solid Plastic Sheets

When choosing solid plastic sheets, several critical factors should be carefully considered to ensure you select the right type for your project. First, evaluate the material's thickness and clarity, as these characteristics greatly influence durability and aesthetic appeal. Thicker sheets typically provide better resistance to impact and weather, making them suitable for outdoor applications. Clarity is vital for projects where visibility is important, such as display cases or signage.

Moreover, consider the specific properties of different plastic materials, such as UV resistance, chemical resistance, and temperature tolerance. For instance, if the sheets will be exposed to sunlight, opt for UV-stabilized options to prevent yellowing and degradation over time. Additionally, assess the intended use: if you require sheets for cutting, drilling, or bending, ensure the material allows for easy fabrication.

**Tips**: Before purchasing, always check customer reviews and product specifications. Opt for samples to test in your environment, ensuring they meet all your project needs. Additionally, consulting with industry professionals can provide insights into the best practices for installation and maintenance of your solid plastic sheets.

Top Solid Plastic Sheets Uses Benefits and Buying Guide

| Dimensional Category | Common Uses | Benefits | Buying Considerations |

|---|---|---|---|

| Thickness: 1/8 inch | Signage, Displays | Durability, Lightweight | Check for UV resistance |

| Thickness: 1/4 inch | Protective Barriers, Machine Guards | Impact Resistance, Easy to Clean | Consider weight for installation |

| Thickness: 1/2 inch | Furniture, Industrial Applications | Long-lasting, Customizable | Evaluate heat resistance |

| Thickness: 3/4 inch | Acrylic Displays, Custom Parts | High Clarity, Weather Resistance | Assess transparency needs |

| Thickness: 1 inch | Construction, Heavy-Duty Applications | Superior Strength, Chemical Resistance | Look for surface finish options |

Maintenance and Care Tips for Longevity of Solid Plastic Sheets

To ensure the longevity of solid plastic sheets, proper maintenance and care are essential. Regular cleaning should be undertaken with mild detergents and soft cloths to prevent scratching and damaging the surface. Avoid using abrasive materials or harsh chemicals that could compromise the integrity of the plastic. It is advisable to clean them frequently, especially in environments prone to dust and grime, which can dull their appearance over time.

In addition to cleaning, it is important to protect solid plastic sheets from extreme temperatures and direct sunlight. High heat can warp or discolor the material, while UV exposure might lead to fading. Utilizing protective coatings or treatments can enhance their resistance to these environmental factors. Moreover, storing plastic sheets in a flat position when not in use will help prevent physical deformities and ensure they remain in optimal condition for years to come. With consistent care, solid plastic sheets can maintain their functionality and aesthetic appeal effectively.

Top Solid Plastic Sheets Uses and Benefits

This bar chart illustrates the frequency of usage for different applications of solid plastic sheets, showcasing their versatility in various industries.

Related Posts

-

What are Solid Plastic Sheets? A Comprehensive Guide to Their Uses and Benefits

-

Top 7 Benefits of Using Opaque Polycarbonate in Modern Architectural Design

-

How to Choose the Best Polycarbonate Multiwall Panels for Your Project

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

How to Use Opaque Plastic Sheeting for Effective Light Blockage and Privacy

-

Top Benefits of Using Coloured Plastic Sheets in 2025 for Your Projects