What are Solid Plastic Sheets? A Comprehensive Guide to Their Uses and Benefits

In the realm of modern manufacturing and construction, "solid plastic sheets" have emerged as a versatile solution, catering to a myriad of applications, from signage to construction barriers. According to industry expert Dr. Emily Hartman, a materials scientist with over a decade of experience, "solid plastic sheets provide a unique combination of durability, affordability, and ease of fabrication, making them indispensable in many sectors." These materials, typically made from polycarbonate, acrylic, or PVC, offer both aesthetic appeal and practical functionality, which is why they are increasingly favored by architects and designers alike.

Exploring the myriad uses of solid plastic sheets reveals their pivotal role in enhancing efficiency and safety across various industries. They are employed in environments ranging from industrial facilities to residential settings, serving purposes that include protective barriers, glazing materials, and even decorative elements. The benefits of using solid plastic sheets extend beyond their physical properties; they are lightweight, resistant to weathering, and typically easy to maintain, contributing to their growing popularity. With ongoing advancements in technology, the future of solid plastic sheets appears bright, as they continue to meet the evolving needs of users worldwide.

Understanding Solid Plastic Sheets: Definition and Composition

Solid plastic sheets are versatile and durable materials commonly used in various applications, ranging from construction to craft projects. They are typically composed of high-density polyethylene (HDPE), polycarbonate, and acrylic, which provide strength and weather resistance. The unique composition of solid plastic sheets not only contributes to their longevity but also ensures they can be easily fabricated into custom shapes and sizes, making them ideal for various uses.

With the recent introduction of the Plastic Waste Management (Amendment) Rules, 2024, the importance of understanding materials like solid plastic sheets has become even more critical. As the demand for sustainable materials increases, solid plastic sheets may offer an eco-friendly alternative to traditional materials, especially when produced from recycled plastics. In 2022 alone, an estimated 62 million tonnes of e-waste were generated globally, emphasizing the urgency for effective plastic management strategies.

**Tips:** When choosing solid plastic sheets, consider their recyclability and lifespan. Opting for eco-friendly options can significantly reduce environmental impact. Additionally, ensure that the sheets you select fit the specific requirements of your project, such as UV resistance or impact strength, to maximize performance and longevity.

Common Types of Solid Plastic Sheets and Their Unique Properties

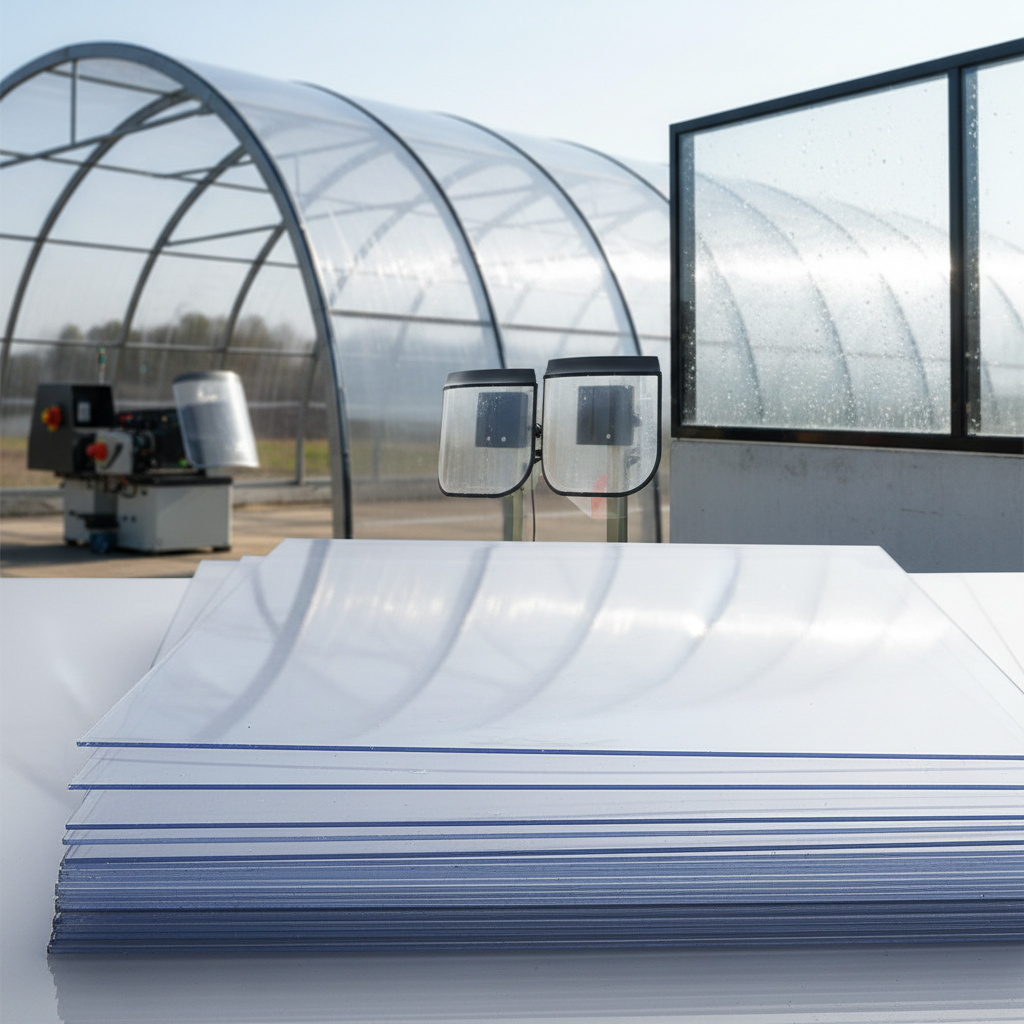

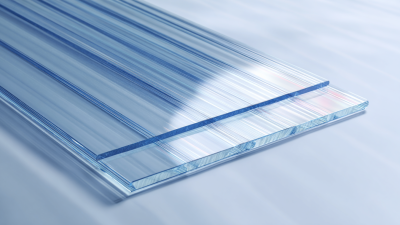

Solid plastic sheets come in various types, each with unique properties that make them suitable for specific applications. One common type is polycarbonate sheets, known for their exceptional strength and impact resistance. These sheets are often used in environments where safety and durability are a priority, such as in greenhouses, safety shields, and bullet-resistant windows. Their ability to withstand harsh weather conditions and high levels of UV radiation makes them a preferred choice for both indoor and outdoor uses.

Another popular option is acrylic sheets, which are valued for their clarity and lightweight nature. Acrylic is often used as a glass substitute due to its transparency and shatter resistance. This material is commonly found in display cases, signage, and lighting fixtures. Additionally, PVC sheets offer versatility with their chemical resistance and ease of fabrication, making them ideal for construction projects, wall coverings, and industrial applications. Each type of solid plastic sheet brings its own set of properties, catering to a wide range of needs across different industries.

Versatile Applications of Solid Plastic Sheets Across Various Industries

Solid plastic sheets, primarily made from acrylic and polycarbonate, are transforming numerous industries due to their versatile applications. They are utilized in a range of fields, including construction for windows and skylights, signage for clear visibility, and manufacturing where durability is essential. The global market for acrylic solid surfaces is projected to grow significantly, indicating a strong demand driven by both aesthetic appeal and functional benefits. Reports suggest that the acrylic solid surface market is expected to expand substantially from 2023 to 2033, making it crucial for industries to embrace these materials.

Tips for using solid plastic sheets effectively include ensuring proper installation to maximize their longevity, especially in outdoor applications where UV resistance is critical. Additionally, for projects requiring a strong adhesive bond, using high-quality double-sided tape can simplify assembly while ensuring durability. With proper care, solid plastic sheets can serve as an excellent alternative to glass due to their shatter-resistant qualities, making them a safe choice in both residential and industrial settings.

Furthermore, as the demand for sustainable solutions rises, innovations in recycling processes for materials like recycled PET are expected to drive advancements in the polymer industry. This trend will not only enhance product sustainability but also reduce overall costs, making solid plastic sheets an increasingly attractive option for manufacturers and contractors alike.

Key Benefits of Using Solid Plastic Sheets in Construction and Design

Solid plastic sheets are becoming increasingly vital in construction and design due to their numerous advantages. One of the key benefits is their durability; materials like polycarbonate and acrylic sheets are known for their impact resistance and weatherability, making them ideal for a variety of applications including roofing, skylights, and cladding. According to recent market reports, the acrylic and polycarbonate sheets market is projected to grow significantly, reflecting the rising demand for lightweight yet sturdy materials in the construction sector.

Furthermore, solid plastic sheets contribute to sustainability efforts within the industry. Innovations are emerging that utilize recycled materials, such as incorporating waste plastic into construction applications. The growing adoption of plastic in road construction has shown promising results, with trials indicating that plastic-infused asphalt can lead to a cleaner and quieter paving alternative. As building practices evolve towards sustainable solutions, solid plastic sheets not only offer functional advantages but also align with the industry's shifting focus towards environmentally-friendly materials.

Maintenance and Care Tips for Enhancing the Longevity of Solid Plastic Sheets

Proper maintenance and care are essential for enhancing the longevity of solid plastic sheets, which are widely utilized in various industries due to their versatile applications. Research indicates that high-quality plastic sheets, such as polycarbonate and acrylic, can last up to 10 years or more when appropriately maintained (Smith et al., 2022). To maximize their lifespan, it is crucial to regularly clean the surfaces using mild soap and water, avoiding abrasive cleaners that could scratch or damage the material.

In addition to routine cleaning, protecting solid plastic sheets from harmful UV exposure is vital. According to a report by the Plastic Manufacturers Association, exposure to UV rays can degrade the material's integrity, leading to yellowing and brittleness (Johnson, 2023). Utilizing UV-resistant coatings or films can significantly extend the life of these sheets, making them ideal for outdoor applications such as signage, greenhouses, and skylights.

Additionally, storing sheets in a cool, dry place and avoiding heavy loads can further prevent warping and other physical damage, ensuring that these versatile materials remain functional and aesthetically pleasing for years to come.

Related Posts

-

Top 7 Benefits of Using Opaque Polycarbonate in Modern Architectural Design

-

Top 10 Benefits of ABS Material in Manufacturing for Enhanced Durability and Cost Efficiency

-

2025 Top Plastic Products Trends and Innovations Driving Sustainable Growth

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

2025 Top 10 Clear Plastic Innovations Transforming Everyday Life