What is a Plastic Board and Its Best Uses?

In today's world, plastic boards have become essential materials in various industries. Experts emphasize their versatile nature. John Smith, a pioneer in the plastic board industry, once said, “Plastic boards are revolutionizing how we think about materials.”

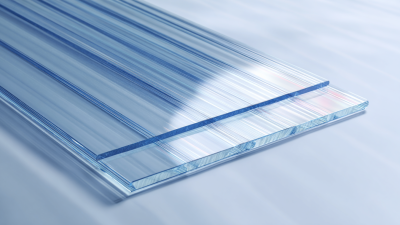

Plastic boards come in various forms, including sheets, panels, and custom shapes. They are lightweight, durable, and moisture-resistant, making them ideal for many applications. For instance, they are commonly used in construction, signage, and crafts. However, the environmental impact of plastic production is a growing concern.

Many people are unaware of the potential downsides of using plastic boards. While they are practical, the need for recycling and sustainability cannot be ignored. As consumers, reflecting on how we use these materials is crucial. We must consider both their benefits and their environmental footprint.

What is a Plastic Board? Definition and Composition Overview

A plastic board is a versatile material made from synthetic polymers. It can be rigid or flexible, depending on the type of plastic used. Commonly, materials like polyethylene and polypropylene are used in its creation. The composition provides strength and durability, making it suitable for various applications.

Plastic boards are often lightweight and resistant to moisture and chemicals. Their use in construction is widespread. They serve as sheathing, insulation, or even scaffolding. In crafting, plastic boards can be cut and shaped easily. Artists and hobbyists appreciate their versatility. Yet, some struggle with the learning curve of working with this medium.

Despite the advantages, plastic boards have environmental implications. Their production and disposal can lead to pollution. Alternatives exist, but they may not offer the same ease of use. Many users find it essential to balance functionality with eco-friendliness. Experimentation often leads to innovative uses, but this comes with responsibility.

What is a Plastic Board and Its Best Uses?

| Characteristic | Description | Common Uses |

|---|---|---|

| Material Composition | Made primarily from polymers such as PVC, HDPE, or polypropylene. | Used in various applications due to versatility. |

| Durability | Resistant to corrosion, chemicals, and moisture. | Ideal for outdoor settings and industrial applications. |

| Weight | Lightweight compared to wood or metal alternatives. | Popular in portable applications and temporary structures. |

| Customization | Can be easily cut, shaped, and colored for specific applications. | Used in signage, displays, and personalized projects. |

| Cost-effectiveness | Generally more affordable than wood or metal. | Widely used in budget-sensitive applications. |

Historical Development of Plastic Boards and Their Evolution in Usage

The journey of plastic boards dates back to the early 20th century. Initially, they were crafted from natural materials, such as ivory and wood. The invention of synthetic materials changed everything. In the 1940s, plastic became widely adopted. The introduction of versatile polymers paved the way for new applications.

As industries grew, so did the uses of plastic boards. They found homes in construction, advertising, and interior design. Plastic boards were lightweight, durable, and weather-resistant. These qualities made them ideal for outdoor signage and temporary structures. However, the environmental impact of plastic use raised concerns. In recent years, calls for recycling and sustainability have intensified.

The evolution continues as technology advances. Newer composites and biodegradable options are emerging. Designers push the boundaries of aesthetics and functionality. Still, questions remain about long-term effects. Balancing innovation with responsibility is a challenge. As society progresses, finding harmony in usage becomes crucial for the future of plastic boards.

Key Properties of Plastic Boards: Durability, Flexibility, and Lightweight

Plastic boards have gained popularity due to their unique properties. Their durability stands out, making them ideal for various applications. According to a recent industry report, plastic boards can last over 25 years with minimal maintenance. This longevity is appealing for both commercial and residential use.

Another key property is flexibility. Plastic boards can be easily shaped and molded to fit different needs. This makes them great for construction, crafting, and even automotive parts. For instance, architects often use plastic boards for signage and interior design elements. They are not only versatile but also lightweight, weighing considerably less than wood or metal. This feature simplifies transportation and installation.

Tips: When choosing a plastic board, consider its thickness. Thicker boards provide better durability for heavy-duty applications. Look for UV-resistant options if outdoor use is planned. Remember, while plastic boards are strong and flexible, they may not perform well in extreme temperatures. Always assess the specific conditions where you intend to use them.

Durability, Flexibility, and Lightweight Properties of Plastic Boards

Common Applications of Plastic Boards Across Various Industries

Plastic boards are versatile materials used in various industries. They can be found in construction, signage, and even in furniture manufacturing. Their lightweight nature and durability make them ideal for many applications. In construction, plastic boards serve as insulation or sheathing. They can withstand moisture and resist corrosion. This makes them favorable for both indoor and outdoor use.

In signage, plastic boards offer bright colors and easy customization. They can be molded into different shapes, making them ideal for marketing displays. With minimal maintenance, these boards maintain their appearance over time.

**Tip:** Always consider the specific requirements of your project. Not all plastic boards are created equal. Choose materials that best fit your needs.

Additionally, plastic boards have found their way into furniture design. They can be cut and shaped into modern furniture pieces. However, the ease of working with plastic boards can lead to mistakes. It's essential to plan carefully before cutting.

**Tip:** Practice your cutting techniques on scrap materials first. This will help you avoid costly errors. Remember to measure twice, cut once.

Future Trends and Innovations in Plastic Board Technology and Sustainability

Plastic boards are evolving rapidly. Innovations focus on sustainability, which is vital for our environment. Manufacturers are exploring biodegradable materials to create more eco-friendly options. This shift addresses growing concerns about plastic waste. Recycled plastics are making a statement, too. They offer robust performance without contributing to landfill issues.

Future trends indicate an increase in multifunctional plastic boards. These boards are designed to serve various purposes, appealing to diverse industries. Moreover, advances in technology enhance their properties. For example, stronger, lighter boards are becoming available. Smart plastic boards with integrated sensors may change how we use them.

However, challenges remain. The production process often requires energy-intensive methods. This raises questions about the overall carbon footprint. We need to ponder ways to optimize these processes. Balancing performance and sustainability is crucial for future success. Regular reflection on these issues will guide us toward better solutions.

Related Posts

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

Top Benefits of Using Solid Polycarbonate Clear Sheets for Your Projects

-

Top 10 Benefits of ABS Material in Manufacturing for Enhanced Durability and Cost Efficiency

-

Why is Clear Plastic the Best Choice for Your Next Project

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

The Ultimate Guide to Choosing the Best Transparent Sheet in 2025