2026 How to Choose Solid Plastic Sheets for Your Next Project?

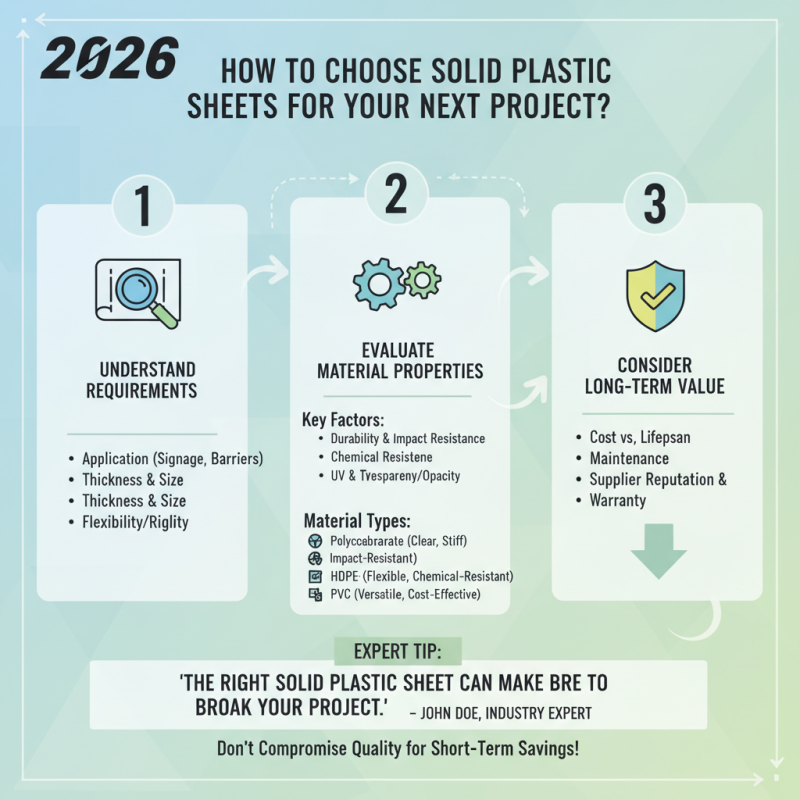

Choosing the right material for your project is crucial. Solid plastic sheets are a popular option for many applications. According to industry expert John Doe, “The right solid plastic sheet can make or break your project.” This highlights the importance of careful selection.

Solid plastic sheets come in various types and thicknesses. They can be used for everything from signage to protective barriers. Understanding your project requirements is essential. The wrong choice can lead to increased costs or project delays.

Moreover, it’s vital to consider durability and finish. Brands may have similar looks but differing qualities. Not every product labeled as solid plastic sheets will meet your needs. Reflecting on these factors can lead to better decisions. Consider asking yourself: Is the product fit for purpose? Taking the time to evaluate your options will pay off in the long run.

Understanding Different Types of Solid Plastic Sheets Available in 2026

In 2026, the demand for solid plastic sheets continues to grow across various industries. These materials are widely favored for their versatility and durability. Reports indicate that the global market for plastic sheets is projected to reach $5 billion by 2026, indicating strong growth. Key types include acrylic, polycarbonate, and PVC sheets, each offering unique benefits.

Acrylic sheets are known for their clarity and lightweight properties. They provide excellent impact resistance, making them suitable for signs and displays. Polycarbonate sheets, on the other hand, are recognized for their strength and UV resistance. They excel in applications requiring durability, like skylights or greenhouses. Meanwhile, PVC sheets are budget-friendly and easy to work with, often used in construction and interior design.

Choosing the right material can be overwhelming. Each type has its strengths and weaknesses. Acrylic, while visually appealing, can scratch more easily. Polycarbonate is tough but can be more expensive. PVC might not have the same aesthetic appeal but serves practical purposes well. Understanding these trade-offs is crucial for a successful project. Consider your specific needs and environment before making a decision.

Key Factors to Consider When Selecting Solid Plastic Sheets for Projects

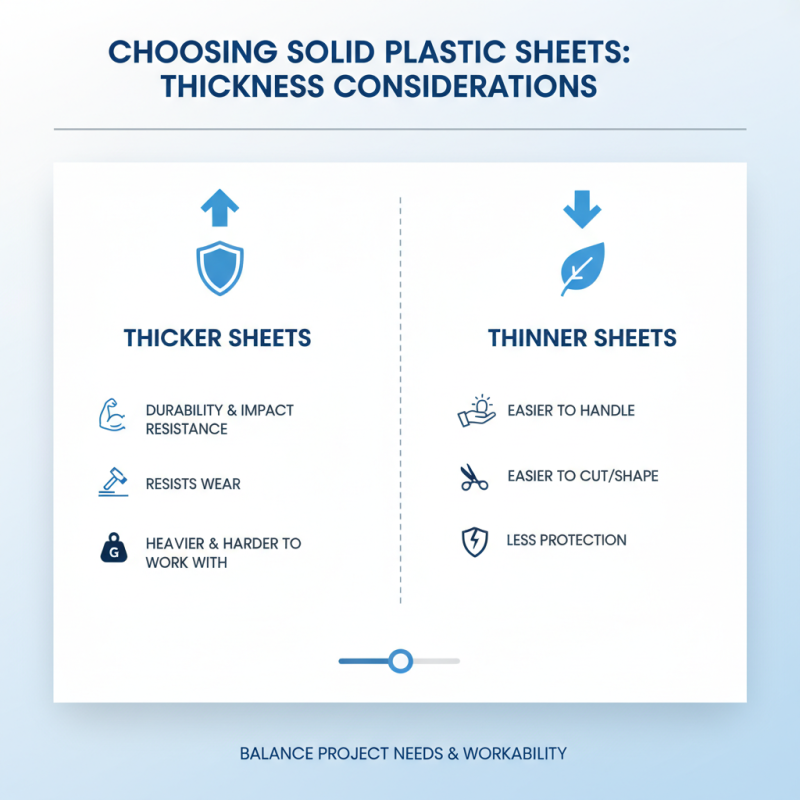

Choosing solid plastic sheets for your project can be challenging. Consider the thickness of the sheets. Thicker sheets provide more durability. They resist impact and wear. However, they may be heavier and harder to work with. On the other hand, thinner sheets are easier to handle but may not offer the same level of protection.

The type of plastic is also crucial. Different materials have varying properties. Some are more flexible, while others are rigid. It's essential to match the plastic's characteristics to your project's needs. For example, flexibility is key for curved surfaces. In contrast, rigidity is better for applications needing stability.

Always check the finish of the sheets. A smooth finish is ideal for visual appeal. A textured surface can enhance grip, but it might collect dirt. A clear sheet allows for light transmission, which may be necessary for certain projects. Keep in mind your project's specific requirements, and don't overlook minor details. Each decision impacts the final outcome.

Comparing Cost and Quality of Various Solid Plastic Sheets

Choosing solid plastic sheets involves balancing cost and quality. Various materials are available, each with unique characteristics. For instance, acrylic sheets offer clarity and durability but can be pricier. Polycarbonate, though more affordable, might not match the visual appeal of acrylic.

When evaluating the cost, consider thickness and size. Thicker sheets typically cost more yet provide better insulation and impact resistance. Cheaper options might be tempting, but they often compromise on quality. It's essential to assess how the material will perform in your specific project. An unsuitable sheet can lead to additional expenses in the long run.

Quality also encompasses factors like UV resistance and flexibility. Some sheets may warp or discolor over time. Testing samples before making a bulk purchase is advisable. Reflect on the intended use: Will the sheet be exposed to outdoor elements? Will it need to withstand heavy wear? These questions help in determining the best choice tailored to your needs.

Applications and Uses of Solid Plastic Sheets in Different Industries

Solid plastic sheets are versatile materials widely used across various industries. They offer durability and resistance to chemicals, making them ideal for applications in construction, signage, and custom fabrication. In the medical field, these sheets can be found in equipment covers, ensuring a sterile environment. Their lightweight nature makes them a popular choice for transportation and packaging as well.

When selecting solid plastic sheets, consider the specific needs of your project. Think about thickness, color, and surface finish. For outdoor applications, UV resistance might be necessary. Always evaluate the mechanical properties, too. They should meet the demands of your environment.

Tips: Measure your project area carefully. Accurate dimensions will save time and materials. Don’t forget to consider how you’ll cut the sheets. Using proper tools is essential for clean edges. Be mindful of the temperature, as extreme heat or cold may affect some plastics.

2026 How to Choose Solid Plastic Sheets for Your Next Project? - Applications and Uses of Solid Plastic Sheets in Different Industries

| Industry | Common Applications | Benefits of Using Solid Plastic Sheets |

|---|---|---|

| Construction | Wall panels, protective barriers | Durability, lightweight, easy to install |

| Automotive | Interior components, signage | Chemical resistance, aesthetic appeal |

| Manufacturing | Equipment guards, conveyor components | Low friction, safety enhancement |

| Healthcare | Medical device casings, barriers | Hygienic, easy to clean, non-toxic |

| Retail | Display cases, signage | Customizable, visual appeal |

Sourcing and Purchasing Solid Plastic Sheets: Tips and Recommendations

When sourcing solid plastic sheets, consider the material type carefully. There are several options available, including acrylic, polycarbonate, and PVC. Each has unique properties and suitability for different applications. Some sheets are UV resistant, while others are more durable against impact. Understanding these differences can influence your project outcome significantly.

Purchasing solid plastic sheets requires attention to detail. Check for thickness options. Thicker sheets typically offer more strength but may be more difficult to work with. It's essential to assess your project needs before making a decision. Quality is equally important. A sheet that looks good may not perform well under stress. It's advisable to request samples when possible.

Pricing can vary widely. Some suppliers may offer attractive deals but compromise on quality. Always compare multiple sources. Don’t rush the decision-making process. Reflecting on your project's requirements can save time and costs later. Pay attention to shipping and handling as well, as it can affect your budget.

2026 Solid Plastic Sheets Selection Criteria

Related Posts

-

Top 10 Benefits of ABS Plastic You Need to Know in 2023

-

2025 How to Choose Clear Plastic Sheets for Maximum Durability and Versatility

-

Top 10 Benefits of Using Coloured Sheets for Your Home and Office

-

Ultimate Tips for Using Opaque Plastic Sheeting Effectively?

-

How to Use Opaque Plastic Sheeting for Effective Light Blockage and Privacy

-

What are Solid Plastic Sheets? A Comprehensive Guide to Their Uses and Benefits