10 Essential Tips for Choosing the Right PVC Sheets for Your Projects

In the contemporary construction and manufacturing landscape, PVC sheets have emerged as a pivotal material due to their versatility and durability. According to a report by Allied Market Research, the global PVC sheet market is projected to reach a value of USD 12.6 billion by 2027, growing at a CAGR of 5.1% from 2020 to 2027. This growth is fueled by the increasing demand for lightweight, moisture-resistant, and cost-effective materials across various industries including construction, automotive, and signage.

When selecting the right PVC sheets for your projects, understanding the various options available is crucial. The right choice can enhance the overall functionality and aesthetic appeal of your project, while also ensuring compliance with industry standards. For example, clarity in sheets is essential for applications requiring transparency, while thickness and gauge can significantly impact durability and practicality. Consideration for the sheet's density, surface finish, and compatibility with other materials can further guide your decision-making process. As the market continues to evolve with innovations, being informed on these essential factors can yield significant long-term benefits for your projects.

Understanding PVC Sheets: Types and Their Applications

PVC sheets are versatile materials widely used across various industries due to their durability, affordability, and ease of maintenance. Understanding the different types of PVC sheets—such as rigid, flexible, foamed, and expanded—is essential for selecting the right one for your project. For instance, rigid PVC sheets are commonly employed in signage and displays, while flexible PVC sheets find their application in upholstery and packaging. According to a report by Research and Markets, the global PVC sheets market is expected to grow steadily, driven by the increasing demand for lightweight and cost-effective materials in construction and automotive sectors.

When choosing PVC sheets, it’s crucial to consider the specific requirements of your project. Tip 1: Assess the application context to determine if a rigid or flexible sheet is needed. For projects requiring significant structural integrity, rigid PVC sheets are preferable, while flexible sheets work best for applications that demand bending and adaptability. Tip 2: Evaluate the thickness and finish of the sheets. A standard thickness range is between 1mm to 12mm; thicker sheets offer greater rigidity, which might be essential for certain applications.

Furthermore, understanding the environmental impact of PVC materials is becoming increasingly important. Many manufacturers are now producing eco-friendly options that comply with environmental regulations. Tip 3: Always confirm the sustainability certifications of the PVC sheets you are considering, as this can reflect their impact on the environment and potentially enhance your project's overall value. By taking these factors into account, you can make an informed decision that aligns with both your project needs and sustainability goals.

Comparison of PVC Sheet Types and Their Applications

Key Factors to Consider When Choosing PVC Sheets

When selecting the right PVC sheets for your projects, there are several key factors to consider that can significantly impact the outcome of your work. First and foremost, think about the thickness of the sheets. Thicker PVC sheets tend to be more durable and resistant to impacts, making them ideal for projects that require extra strength. On the other hand, thinner sheets may offer more flexibility and ease of installation, which could be beneficial depending on your specific application.

Another important aspect is the type of finish you prefer. PVC sheets come in various finishes—glossy, matte, or textured—that can influence both the aesthetic appeal and functionality of your project. For instance, a glossy finish can enhance light reflection and is easier to clean, whereas a matte finish can provide a more sophisticated look.

Additionally, consider the environmental conditions where the sheets will be used. UV resistance is essential for outdoor applications, ensuring that the material will not degrade under sunlight. Moreover, evaluate the chemical resistance of the PVC sheets if your project involves exposure to harsh substances. These factors will ensure that your chosen sheets effectively meet the demands of your project and maintain their integrity over time.

Evaluating Thickness and Durability of PVC Sheets

When selecting PVC sheets for your projects, evaluating their thickness and durability is crucial to ensuring they meet your application requirements. Thickness is measured in millimeters, and it typically ranges from 1mm to 10mm or more. According to industry reports, a thickness of 3-5mm is often recommended for general-purpose applications, as this range provides a good balance between flexibility and strength. Thicker sheets generally offer greater durability, making them more suitable for demanding environments. For instance, a 5mm sheet may withstand higher impact and stress compared to its 1mm counterpart, making it ideal for commercial uses such as signage, partitioning, or protective barriers.

Durability also encompasses resistance to environmental factors, including UV exposure, chemicals, and temperature fluctuations. Research indicates that certain PVC formulations, when combined with stabilizers and additives, can significantly enhance the material's resistance to degradation, extending its lifespan in outdoor settings. Studies have shown that high-quality PVC sheets can last over 10 years, even when exposed to harsh weather conditions. Furthermore, ensuring proper thickness coupled with suitable additives can ensure that the PVC sheets maintain their structural integrity and aesthetic quality over time. Therefore, when choosing PVC sheets, carefully assess both the thickness and the specified durability ratings to optimize performance for your specific project needs.

10 Essential Tips for Choosing the Right PVC Sheets for Your Projects - Evaluating Thickness and Durability of PVC Sheets

| Tip No. | Tip Description | Recommended Thickness (mm) | Durability Rating |

|---|---|---|---|

| 1 | Consider the application for which you need the PVC sheets. | 2-3 | Medium |

| 2 | Evaluate environmental conditions (UV exposure, moisture, etc.). | 4-5 | High |

| 3 | Select sheets that offer resistance to chemicals relevant to your project. | 3-4 | Medium |

| 4 | Look for PVC sheets with reinforced edges for better durability. | 5 | High |

| 5 | Check the impact resistance rating for higher durability. | 3-6 | High |

| 6 | Ensure the thickness fits your project requirements (e.g., stiffness). | 2-4 | Medium |

| 7 | Consult technical data sheets for specific performance metrics. | N/A | N/A |

| 8 | Consider fire ratings if applicable to your project. | Varies | Medium to High |

| 9 | Assess the surface finish for aesthetic and functional needs. | 2-5 | Variable |

| 10 | Compare prices across suppliers for the best value. | N/A | N/A |

Cost and Budget Considerations for PVC Sheets

When selecting PVC sheets for your projects, understanding cost and budget considerations is crucial. PVC sheets come in various grades and thicknesses, which directly influence their price. Before diving into a purchase, it’s essential to outline your project’s specifications and requirements. Consider the application—whether it’s for signage, construction, or design—as this will inform the quality and type of PVC needed. By assessing your needs, you can initiate a more focused search, potentially avoiding costly errors down the line.

Another critical aspect of budgeting for PVC sheets is factoring in additional costs beyond the material itself. Shipping fees, cutting services, and custom sizes can significantly affect the overall budget. It’s wise to collaborate with suppliers who offer transparent pricing structures and detailed quotations. Taking the time to compare different suppliers can also yield better deals, especially if you’re purchasing in bulk. Keeping an eye on ongoing promotions or discounts can further aid in optimizing your budget, allowing for a more economical choice without compromising on quality.

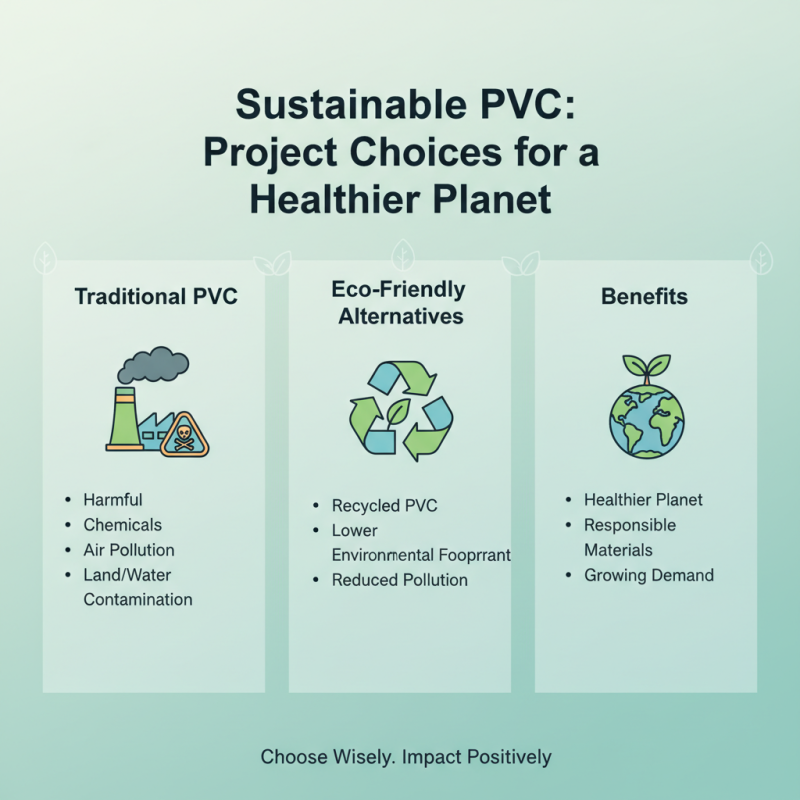

Sustainability and Environmental Impact of PVC Choices

When selecting PVC sheets for your projects, it's crucial to consider the sustainability and environmental impact of your choices. Traditional PVC production can release harmful chemicals and pollutants, which not only affect air quality but also contribute to land and water contamination. Opting for eco-friendly alternatives, such as recycled PVC or sheets manufactured with lower environmental footprints, can significantly reduce these negative effects. By prioritizing sustainability, you not only contribute to a healthier planet but also align your projects with the growing demand for environmentally responsible materials.

In addition to recycling, it's important to look at the lifecycle of PVC sheets. Assessing their durability, recyclability, and potential for reuse can guide your decision-making process. Some manufacturers have embraced innovations that improve the environmental performance of PVC, such as additives that enhance photodegradability or formulations that are free from harmful phthalates. Understanding these advancements allows consumers and businesses to make informed choices that lessen their ecological footprint. As awareness of environmental issues continues to grow, incorporating sustainable practices into your material selection will enable you to create projects that are not only efficient but also environmentally conscious.

Related Posts

-

The Ultimate Guide to Choosing the Best Transparent Sheet in 2025

-

2025 Top 10 Clear Plastic Innovations Transforming Everyday Life

-

2025 How to Choose Clear Plastic Sheets for Maximum Durability and Versatility

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

Top 7 Benefits of Using Opaque Polycarbonate in Modern Architectural Design

-

Top Benefits of Using Coloured Plastic Sheets in 2025 for Your Projects