Ultimate Tips for Using Opaque Plastic Sheeting Effectively?

In the world of construction and agriculture, opaque plastic sheeting plays a crucial role. According to a report by Smith Research, the demand for opaque plastic sheeting has risen by 25% over the last five years. This surge is attributed to its versatility and effectiveness in moisture control and light diffusion. As industry expert John Smith notes, "Opaque plastic sheeting is indispensable for maximizing plant growth and ensuring crop protection."

However, using opaque plastic sheeting effectively requires careful consideration. Factors like thickness, UV resistance, and application method can significantly influence performance. Mistakes often happen. Many users underestimate the importance of proper installation. This can lead to inadequate coverage or inefficient light management. For instance, choosing the wrong thickness might result in premature wear or ineffective insulation.

It's essential to recognize that while opaque plastic sheeting is beneficial, it is not a one-size-fits-all solution. Different applications require different approaches. The challenge lies in learning from past experiences. By reflecting on previous usage, users can optimize their strategies for better outcomes. Embracing these insights can lead to improved techniques and more productive results.

Understanding Opaque Plastic Sheeting: Features and Benefits

Opaque plastic sheeting has several unique features and benefits. It provides excellent light blockage, making it perfect for situations where sunlight must be restricted. This feature is beneficial for creating darker environments, like during plant growth cycles or photography. Additionally, it offers protection against moisture, dust, and wind, helping to maintain a stable environment.

When using opaque plastic sheeting, consider these tips. First, measure the area accurately before cutting the sheet. A precise measurement can avoid waste and ensure better coverage. Secondly, use weights or adhesives to secure the edges. Loose sheets can flap and damage easily. It’s often overlooked, but securing the edges properly can significantly extend the life of the material.

Another critical aspect is how to maintain it. Check for tears or damage regularly. Small holes can lead to bigger issues over time. Often, users might neglect these details, thinking it's not significant. In reality, frequent checks can prevent costly replacements. Taking the time to care for your opaque plastic sheeting is beneficial in the long term.

Selecting the Right Opaque Plastic Sheeting for Your Project

Selecting the right opaque plastic sheeting for your project involves several key factors. Consider the thickness of the material. Thicker sheeting tends to be more durable but can be harder to handle. A thickness of 6 mil is often sufficient for most projects, yet it may not be right for every situation. Too thin, and it may tear easily.

Also, evaluate the purpose of the sheeting. Are you trying to block light, or create a barrier? Different projects require different levels of opacity. Some options allow minimal light penetration, while others completely block it. Be cautious, as choosing the wrong level may compromise the project's effectiveness.

Texture and finish matter too. Smooth sheeting is easy to clean but may reflect light differently compared to textured options. Think about the design and functional needs of your project. It's okay to feel uncertain about some choices. Doing local tests can help you find what truly works. Don't settle for the first option; explore until it feels right.

Ultimate Tips for Using Opaque Plastic Sheeting Effectively

| Project Type | Sheet Thickness (mil) | Size Options (ft) | UV Resistance | Common Uses |

|---|---|---|---|---|

| Outdoor Greenhouse | 6 | 10 x 100 | Yes | Plant Protection |

| Construction Site | 4 | 20 x 50 | No | Site Protection |

| Event Canopy | 8 | 10 x 20 | Yes | Weather Protection |

| Art Projects | 2 | 5 x 5 | No | Creative Installations |

| Storage Cover | 10 | 12 x 24 | Yes | Equipment Protection |

Effective Techniques for Cutting and Installing Opaque Plastic Sheeting

When it comes to cutting opaque plastic sheeting, the right tools are essential. A sharp utility knife or heavy-duty scissors can make a big difference. Measure your area carefully before cutting. Mark the sheeting with a pencil to ensure straight lines. It's easy to make mistakes, so double-check your measurements. A small error can lead to uneven edges.

Installation is the next important step. Make sure the surface is clean and dry. If you're using the sheeting for a greenhouse, create a tight seal to maintain humidity levels. Tape can be helpful, but it may not always stick well. Consider using clips or fasteners for a more durable hold. Avoid rushing the process; attention to detail will yield better results. Sometimes, the final look doesn’t match initial expectations, and that's okay. Learning from these little bumps can lead to better techniques in the future.

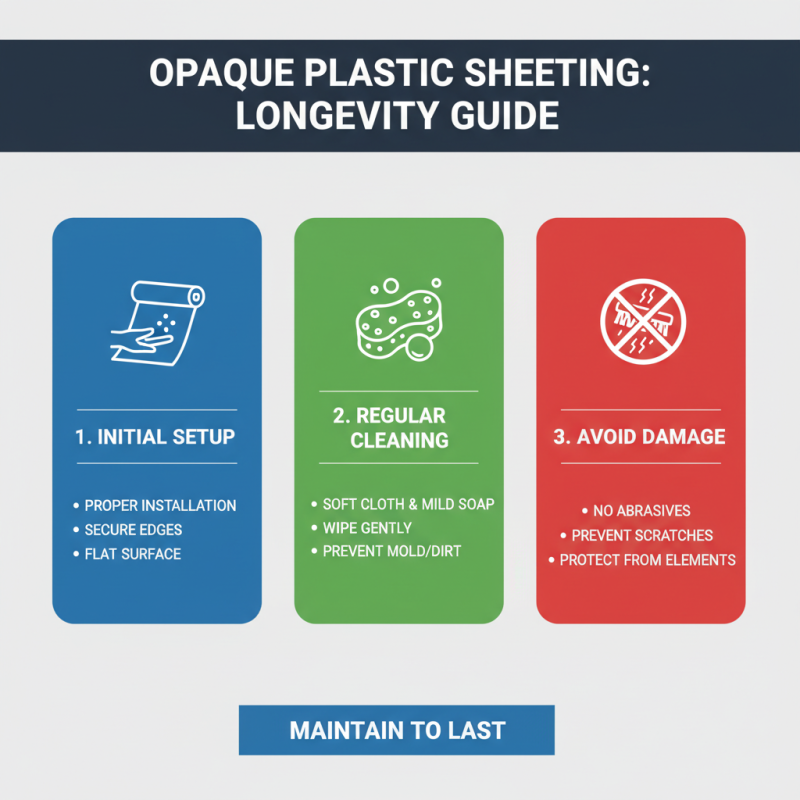

Maintaining and Caring for Opaque Plastic Sheeting Over Time

Maintaining opaque plastic sheeting is essential for its longevity. It's not all about the initial installation. Over time, exposure to elements can wear it down. Regular cleaning is necessary. Mold and dirt can accumulate easily. Use a soft cloth with mild soap to wipe it down. Avoid abrasive materials that can cause scratches.

Store your sheeting properly when not in use. Keep it in a cool, dry place. Direct sunlight can cause fading and deterioration. If you're stacking sheets, ensure they are flat to prevent warping. Regularly inspect the edges for signs of fraying. Small tears can quickly lead to bigger problems.

Reflect on the usage patterns. Are there areas where the sheeting is more likely to fail? If you notice frequent damage, consider additional protective measures. It’s okay to learn through mistakes. Take note of what works and what doesn't. This reflection will help you improve your care routine over time.

Common Mistakes to Avoid When Using Opaque Plastic Sheeting

When using opaque plastic sheeting, many make critical mistakes that hinder their effectiveness. One common error is neglecting surface preparation. A clean, dry surface ensures better adhesion and durability. Reports indicate that improper surface conditions can reduce the lifespan of plastic sheeting by up to 30%. Skipping this step might save time but can be costly in the long run.

Another issue arises from incorrect measurements. Miscalculating dimensions leads to excess waste and additional costs. In a study, it was found that 20% of plastic sheeting is unnecessarily discarded due to measurement errors. Taking the time to accurately measure before cutting can enhance both sustainability and project efficiency.

Tips for using opaque plastic sheeting include ensuring proper ventilation when applying adhesive. Lack of airflow can create bubbles and weaken bonds. Additionally, trim excess sheeting carefully to avoid jagged edges. Proper finishing helps maintain a professional appearance. Reflect on your approach, and make adjustments where needed to improve results.

Related Posts

-

10 Essential Tips for Choosing the Right PVC Sheets for Your Projects

-

What is ABS Sheets and How Are They Used in Different Industries

-

Top Solid Plastic Sheets Uses Benefits and Buying Guide

-

Top 10 Benefits of Using Coloured Sheets for Your Home and Office

-

Top 10 Benefits of ABS Plastic You Need to Know in 2023

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits