How to Choose Transparent Polycarbonate for Your Projects?

Choosing the right materials for your projects is crucial. When it comes to durability and clarity, transparent polycarbonate stands out. It is widely used in various industries, from construction to automotive. According to a recent industry report from the International Polycarbonate Association, the demand for transparent polycarbonate is expected to grow by 5% annually. This growth reflects its versatility and strength.

Industry expert Dr. Emily Chan once stated, "Transparent polycarbonate opens new possibilities for design and function." Her insights highlight the importance of selecting this material wisely. Transparent polycarbonate is not just a clear choice; it also provides exceptional impact resistance and UV protection. However, one must consider the specifications carefully. Not all products labeled as transparent polycarbonate meet the same quality standards.

Projects may require specific grades or thicknesses, which can vary significantly. This often leads to confusion and errors. It's essential to evaluate suppliers and their offerings thoroughly. Reflecting on these decisions can enhance the success of your project, minimizing potential setbacks. Transparent polycarbonate can be a game-changer, but you must navigate its complexities wisely.

Understanding the Basics of Transparent Polycarbonate

Transparent polycarbonate is a versatile material often used in various projects. It combines strength and clarity, making it a popular choice for both functional and aesthetic applications. Understanding the basics is essential for selecting the right polycarbonate for your needs.

Begin by considering the thickness of the material. Thicker sheets provide more durability, while thinner sheets are lighter and easier to manipulate. Transparency ranges from crystal clear to slightly tinted. For projects requiring maximum light transmission, choose high-clarity versions. However, tinted options can reduce glare, which may be beneficial in certain settings.

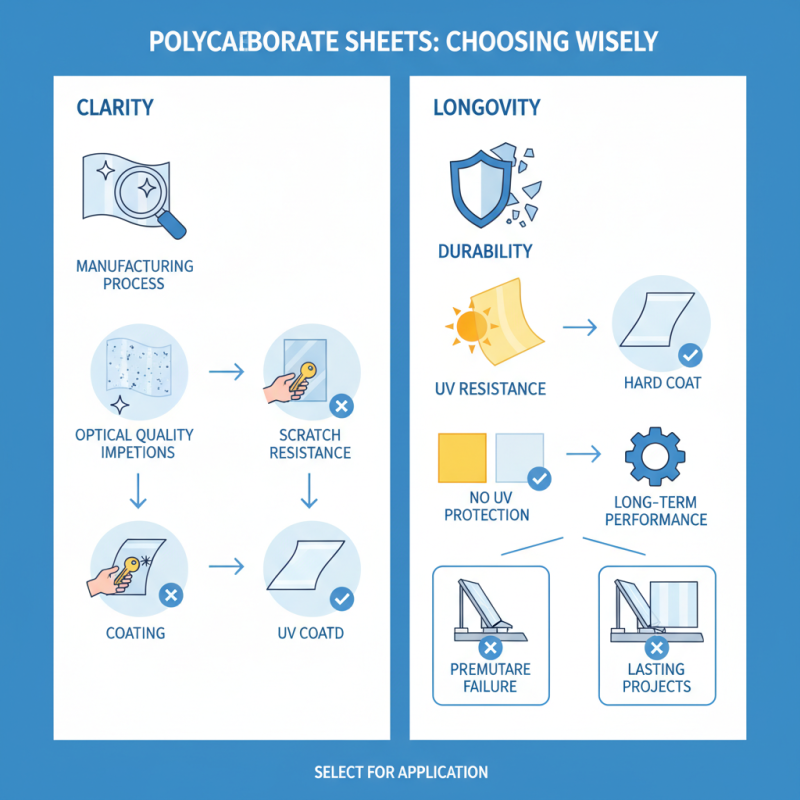

Another aspect to reflect on is the UV resistance. Not all polycarbonate sheets are created equal in this regard. Some offer protection from harmful rays, while others do not. Consider your project’s environment. If it's outdoors, UV protection is critical to avoid degradation over time. While polycarbonate can withstand impact, improper installation may lead to complications. Always think about the long-term performance and be ready to adapt your choices.

Evaluating the Key Properties of Polycarbonate Materials

When choosing transparent polycarbonate for your projects, evaluating its key properties is essential. Polycarbonate is known for its high impact resistance. It is significantly tougher than glass. This makes it a popular choice for safety applications. Its clarity is remarkable, often rivaling that of acrylic. Yet, it is important to note that exposure to UV light can lead to yellowing over time. This is a factor to consider based on the project’s location.

Another critical property is its thermal stability. Polycarbonate can withstand higher temperatures without losing shape. However, it must be kept in mind that extreme heat can still cause warping. The material also offers good chemical resistance but can be susceptible to certain solvents. Understanding these limitations is vital when planning your use cases. This knowledge allows for better decision-making tailored to specific environments and conditions.

Moreover, polycarbonate sheets are lightweight, making them easy to handle and install. Yet, this same feature can sometimes lead to misconceptions about their durability. Lightness does not always mean fragility; rather, it points to versatility. Proper installation can maximize its benefits and minimize flaws that may arise from improper handling.

How to Choose Transparent Polycarbonate for Your Projects? - Evaluating the Key Properties of Polycarbonate Materials

| Property | Description | Typical Values |

|---|---|---|

| Light Transmission | The amount of light that can pass through the polycarbonate. | Up to 88% |

| Impact Resistance | Resistance to breakage and weathering. | 200 times stronger than glass |

| Thermal Insulation | The material's ability to resist heat flow. | R-value: 1.2 to 2.5 |

| Weight | Lightweight nature compared to glass or acrylic. | 1.2 - 1.4 g/cm³ |

| UV Resistance | Protection against ultraviolet light degradation. | UV-protected options available |

| Chemical Resistance | Resistance to chemicals and solvents. | Moderate resistance |

Identifying Suitable Applications for Transparent Polycarbonate

Transparent polycarbonate is a versatile material suitable for various applications. Its strength and clarity make it ideal for safety glasses and protective barriers. For designers, using this material can enhance aesthetics while ensuring durability. Consider applications like skylights and greenhouses, where light transmission is crucial.

However, it is essential to reflect on the project requirements before making a choice. Not all transparent polycarbonates are the same. Different grades exist, with varying resistance to UV rays and impact. Some may scratch easily, affecting clarity over time. Projects that require frequent cleaning or exposure to harsh conditions need careful material selection.

Additionally, the environmental impact of polycarbonate is a growing concern. While it can be recycled, not all facilities accept it. Seeking alternatives might be needed in specific situations. Evaluating both the advantages and limitations will ensure that the right polycarbonate is chosen for each unique project.

Applications of Transparent Polycarbonate

Factors to Consider When Selecting Polycarbonate Thickness

When selecting the right thickness of transparent polycarbonate for your projects, consider the specific application. Thickness influences durability, insulation, and overall safety. Thicker polycarbonate usually offers better impact resistance. For areas prone to high traffic, consider at least 6 mm thickness.

Tips: Evaluate the environment where your project will be placed. Will it face extreme weather? If so, a thicker sheet is a wise choice. However, don't overlook lighter options for applications like greenhouse panels, which can benefit from lower thickness due to reduced weight.

Keep in mind that not all applications require the thickest material available. A balance between flexibility and strength is essential. Sometimes, thinner sheets may be adequate. Reflect on your project's needs, and don't always opt for the heavy-duty option. It may lead to unnecessary costs and weight. Finding the right polycarbonate thickness is about assessing trade-offs in strength, weight, and cost.

Comparing Different Brands and Products of Polycarbonate Sheets

When selecting transparent polycarbonate sheets, understanding the differences among various products is essential. Different brands may use unique manufacturing processes, affecting clarity and durability. Some sheets might be more prone to scratches. Others may yellow faster over time. These factors can significantly impact your projects' long-term performance.

Color options can also vary widely. Some brands may offer tinted options for specific aesthetics. Clear sheets are popular for greenhouses and projects requiring visibility. However, not all clear sheets are created equal. It's crucial to compare the UV resistance and impact strength of each product. Inadequate protection can reduce the lifespan of your installation. Pay attention to warranties; they often reflect the manufacturer's confidence in their products.

Don't overlook the thickness. Thicker sheets generally provide better insulation and strength. Still, they can be heavier and harder to install. It's important to assess your project's structural needs. Are you prepared for the potential challenges thicker materials might bring? Balancing performance with manageability is key. Careful consideration of these details will guide you toward making an informed choice.

Related Posts

-

Top 7 Benefits of Using Opaque Polycarbonate in Modern Architectural Design

-

What are Solid Plastic Sheets? A Comprehensive Guide to Their Uses and Benefits

-

How to Choose the Best Polycarbonate Multiwall Panels for Your Project

-

Top Solid Plastic Sheets Uses Benefits and Buying Guide

-

The Ultimate Guide to Polycarbonate Multiwall Sheets Benefits and Uses

-

Top 10 Benefits of ABS Plastic You Need to Know in 2023