How to Choose the Right Solid Polycarbonate Sheet for Your Project

When embarking on a project that requires durable and versatile materials, selecting the right solid polycarbonate sheet is crucial for achieving optimal results. Solid polycarbonate sheets are renowned for their exceptional strength, lightweight nature, and excellent optical clarity, making them a popular choice across various industries, from construction to signage. However, with the myriad of options available in terms of thickness, color, and surface treatments, making an informed decision can be daunting.

In this guide, we will explore the key factors to consider when choosing a solid polycarbonate sheet for your specific project needs. Understanding the physical properties, such as UV resistance and impact strength, as well as the aesthetic qualities, including transparency and color variations, will help you narrow down your choices. Moreover, we will discuss practical applications and design considerations that can further influence your selection process. By the end of this guide, you will be equipped with the knowledge necessary to select the perfect solid polycarbonate sheet that not only meets your project requirements but also stands the test of time.

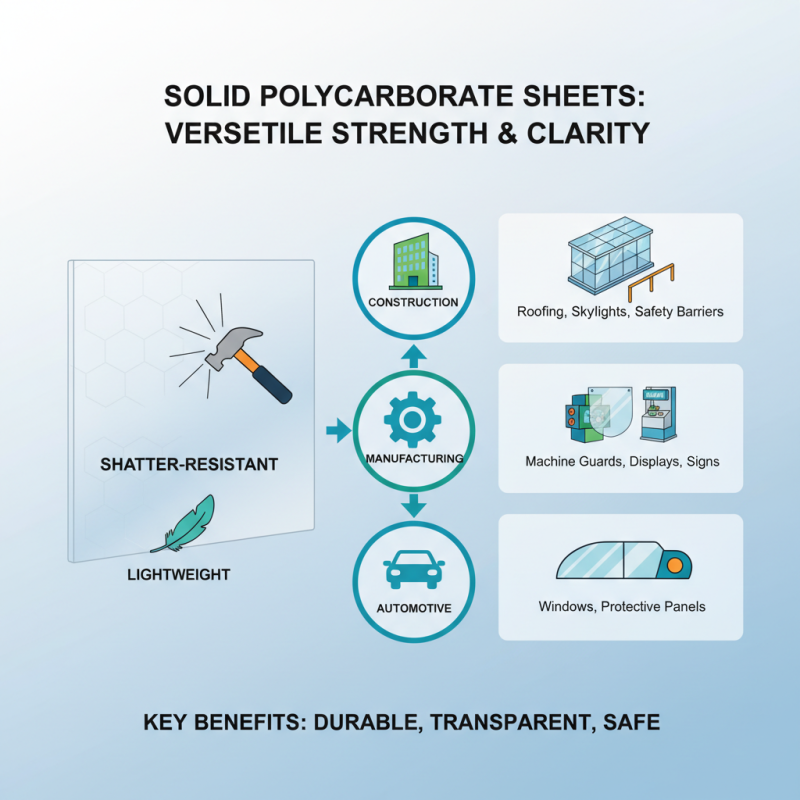

Understanding Solid Polycarbonate Sheets and Their Applications

Solid polycarbonate sheets are versatile materials that find a wide range of applications due to their exceptional strength and clarity. Unlike traditional glass, polycarbonate sheets are lightweight yet shatter-resistant, making them ideal for environments where safety is a concern. They are often used in building projects, such as roofing, skylights, and safety barriers, where transparency and durability are essential. In addition to construction applications, solid polycarbonate sheets are also popular in manufacturing, advertising, and even in the automotive industry for making windows and protective panels.

When choosing solid polycarbonate sheets for your project, consider the specific requirements that align with their functionality. For instance, applications that require UV protection will benefit from sheets that have a UV-resistant coating, while those needing thermal insulation might require multi-wall polycarbonate options instead. The thickness of the sheet can also impact its strength and insulation properties, which should be matched to the demands of your specific use case. Understanding the diverse applications and characteristics of solid polycarbonate sheets is crucial for making an informed decision that optimally meets your project needs.

Evaluating Key Factors for Choosing the Right Thickness and Size

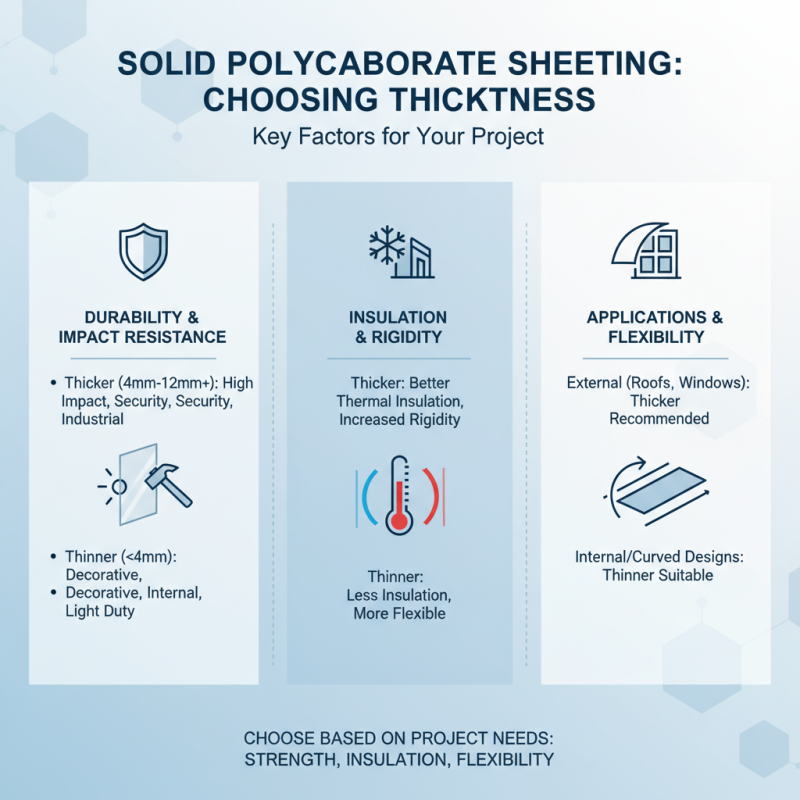

When evaluating key factors for choosing the right thickness of solid polycarbonate sheets, it is essential to consider the specific needs of your project. The thickness of the sheet can significantly impact its performance attributes, including durability, insulation, and flexibility. For applications requiring high impact resistance, such as in security or industrial settings, opting for thicker sheets is advisable. Typically, sheets ranging from 4mm to 12mm are suitable for external applications where strength is paramount, while thinner sheets may suffice for internal purposes or decorative uses.

Additionally, the size of the polycarbonate sheet plays a critical role in maximizing efficiency and minimizing waste during installation. It is essential to accurately measure the area where the sheet will be applied, taking into consideration any cuts or alterations required. Standard sizes are available, but custom dimensions can also be obtained to suit unique project requirements. Ensuring that the dimensions match your specifications helps in achieving a seamless fit, thereby enhancing the overall aesthetic and functional quality of the installation. By carefully assessing these factors—thickness and size—you can select the appropriate polycarbonate sheet that best aligns with your project goals.

Comparing Types of Solid Polycarbonate Sheets: Clear, Colored, and More

When selecting a solid polycarbonate sheet for your project, understanding the various types available is crucial. Clear polycarbonate sheets are highly favored for applications requiring exceptional light transmission and clarity. They can transmit up to 90% of visible light, making them a popular choice for greenhouses, skylights, and display cases. According to industry reports, clear polycarbonate is also known for its high impact resistance, capable of withstanding significant force without breaking, which is a key consideration in safety applications.

Colored polycarbonate sheets offer unique benefits, as they can enhance aesthetics and control light transmission properties. They come in an array of colors, which allows for creative designs and can help manage glare in environments like sporting arenas or architectural applications. Research indicates that certain colored sheets can block harmful UV rays while still allowing an optimal amount of visible light, contributing to energy efficiency in buildings. Moreover, when compared to clear sheets, colored options provide a degree of privacy without sacrificing too much luminosity, making them suitable for both residential and commercial settings.

Ultimately, the choice between clear, colored, and other specialty sheets, such as frosted or embossed finishes, should align with the specific requirements of your project. Considerations such as aesthetic appeal, light control, and durability will significantly impact the performance and functionality of the polycarbonate you select, guiding you toward the most suitable option.

Comparison of Solid Polycarbonate Sheet Types

Assessing Durability and Weather Resistance for Specific Environments

When selecting solid polycarbonate sheets for your project, assessing durability and weather resistance specific to your environment is crucial. Polycarbonate sheets are renowned for their exceptional impact resistance—up to 250 times stronger than glass—making them suitable for high-traffic areas or structures exposed to severe conditions. Reports from the Polycarbonate Manufacturers Association highlight that polycarbonate maintains structural integrity in temperatures ranging from -40°F to 240°F, ensuring versatility in various climates.

Weather resistance is another critical factor. High-quality polycarbonate sheets are often coated with a UV protection layer that extends their lifespan by preventing yellowing and degradation due to sun exposure. According to studies conducted by the American Society for Testing and Materials, polycarbonate sheets can withstand harsh weather elements, including heavy rain and hail, without losing their transparency or mechanical strength.

Tips: When selecting polycarbonate sheets, consider the specific environmental challenges of your project. For outdoor applications, prioritize sheets with UV protection to enhance longevity. Additionally, opt for thicker sheets in areas prone to heavy snowfall or strong winds to provide better load-bearing capabilities. Always consult manufacturer guidelines to ensure you choose the right sheet thickness and coating for your specific needs.

How to Choose the Right Solid Polycarbonate Sheet for Your Project - Assessing Durability and Weather Resistance for Specific Environments

| Property | Polycarbonate Type | Durability Rating | Weather Resistance | Ideal Use Case |

|---|---|---|---|---|

| Impact Resistance | Standard Grade | High | Moderate UV Protection | Greenhouses |

| UV Resistance | UV-Filtered | Very High | Excellent | Outdoor Signage |

| Thermal Stability | Heat Resistant | High | Good | Industrial Applications |

| Light Transmission | Clear Grade | Moderate | Limited UV Protection | Skylights |

| Chemical Resistance | Chemical Grade | High | Moderate | Laboratories |

Identifying Suitable Suppliers for Quality Solid Polycarbonate Products

When selecting suppliers for quality solid polycarbonate products, it’s essential to assess their reputation and reliability. Start by researching potential suppliers online and check for customer reviews and testimonials. Look for companies that have a proven track record of delivering high-quality materials and excellent customer service. A reputable supplier will often have transparent information about their products, including specifications, certifications, and warranties.

Additionally, consider the range of products and services offered by the supplier. A good supplier should provide various thicknesses, colors, and finishes of polycarbonate sheets to suit different project needs. It’s also beneficial if they offer customization options or additional resources, like technical support or guidance on installation. Engaging with suppliers who are knowledgeable about polycarbonate can make a significant difference in ensuring that you choose the right material for your project requirements.

Related Posts

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

How to Choose the Best Polycarbonate Multiwall Panels for Your Project

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

Top Benefits of Using Polycarbonate Sheets for Your Home and Projects

-

Top Solid Plastic Sheets Uses Benefits and Buying Guide

-

2025 Top Plastic Products Trends and Innovations Driving Sustainable Growth