How to Choose the Right Polycarbonate Panels for Your Project?

When embarking on a project that requires polycarbonate panels, making the right choice is crucial. John Smith, a leading expert in the polycarbonate industry, emphasizes, "Selecting the appropriate polycarbonate panels can significantly impact your project's success." With various options available, understanding the types and properties of these panels is essential.

Consider the specific needs of your project. Are you focusing on durability, insulation, or aesthetic appeal? Each aspect plays a vital role. Polycarbonate panels come in different thicknesses and finishes, affecting their performance and appearance. It's easy to overlook these details, which can lead to mistakes in your selection process.

Additionally, don't forget about installation and maintenance. The longevity of polycarbonate panels can hinge on proper installation techniques. Reflect on whether you have the right tools or expertise for the job. Making informed choices can save time and money, but it requires careful consideration and reflection on your project goals.

Types of Polycarbonate Panels and Their Applications

When selecting polycarbonate panels, understanding their types is key. There are two main categories: solid panels and multi-wall panels. Solid panels are thick and strong. They provide excellent impact resistance, making them ideal for high-traffic areas. Multi-wall panels, on the other hand, are lightweight and provide better insulation. They are perfect for greenhouses or skylights, where temperature control matters.

Transparent options are also available. Clear panels allow maximum light transmission. They are suitable for applications where visibility is crucial. Transparent bronze or tinted panels can reduce glare, offering a softer light quality. Both options can create stunning architectural designs. Yet, it’s essential to consider UV protection. Some panels block harmful rays, extending their lifespan.

Reflect on your project's specific needs. Aesthetic appeal is one thing, but functionality is critical too. Will the panel withstand local weather conditions? Heavy rain and strong winds could challenge some choices. Pay attention to panel thickness. Thicker panels are often more durable but can cost more. Make your selection wisely, balancing cost and long-term performance.

Factors to Consider When Choosing Polycarbonate Panels

Choosing the right polycarbonate panels for your project involves several critical factors. One key consideration is the thickness of the panels. Thicker panels offer more insulation and impact resistance. Reports indicate that panels with a thickness of 10 mm to 16 mm can significantly enhance durability. For specific applications, opting for panels around 6 mm may suffice, but they may not withstand heavy impacts.

Another significant factor is the type of polycarbonate used. There are twin-wall, multi-wall, and solid panels available. Twin-wall panels provide good insulation while remaining lightweight. Multi-wall panels, although often pricier, can offer enhanced thermal efficiency. There's a trade-off between cost and performance that must be considered. In a market analysis, over 40% of users reported dissatisfaction with insulation in single-layer panels.

Light transmission and UV filtering should also be taken into account. Some panels allow light to penetrate up to 90%, making them suitable for greenhouses. However, choosing panels with adequate UV protection is vital. Users often find that without proper UV filtration, the material can degrade quickly over time. Understanding these variables can help ensure that your choice meets both functional and aesthetic needs.

Thickness, UV Protection, and Insulation Properties

Choosing the right polycarbonate panels requires careful consideration of thickness, UV protection, and insulation properties. Thickness directly impacts durability and flexibility. For example, panels that are 6mm thick are often used in residential applications. They provide a good balance of strength and weight. However, thinner panels may crack under pressure or extreme weather.

UV protection is crucial for longevity. A recent report indicated that polycarbonate panels with a UV coating can block up to 99% of harmful rays. This feature is important for structures exposed to sunlight. Without protection, panels may yellow over time. This loss of clarity can result in poor aesthetics and decreased performance.

Insulation properties cannot be overlooked. Multi-wall polycarbonate panels can improve thermal efficiency. In a comparison study, these panels reduced heat loss by 20% compared to single-layer options. However, they may also be costlier to install. Balancing initial investment with long-term savings requires careful thought. It highlights the importance of weighing each variable according to your specific project needs.

How to Choose the Right Polycarbonate Panels for Your Project?

| Property | Description | Recommended Range |

|---|---|---|

| Thickness | Determines durability and insulation value. | 2mm to 25mm |

| UV Protection | Protects against damaging UV rays. | Up to 99% UV filtration |

| Insulation Properties | Measures energy efficiency; lower values mean better insulation. | U-value < 1.0 W/m²K |

| Weight | Lightweight material, easy to handle and install. | 0.7 to 2.0 kg/m² |

| Impact Resistance | High resistance to impact, good for safety. | Up to 200 times stronger than glass |

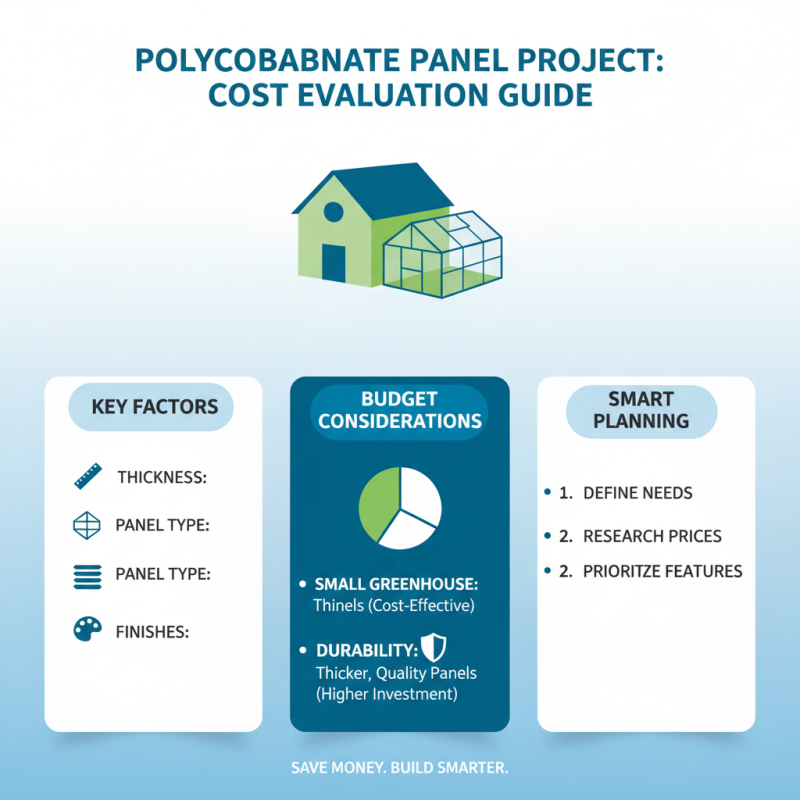

Cost Analysis and Budget Planning for Polycarbonate Panels

When planning a project with polycarbonate panels, cost evaluation is key. Prices can vary widely based on thickness, type, and finishes. Understanding your budget helps prioritize features. For a small greenhouse, a thinner panel might suffice. However, if you’re looking for durability, expect to pay more for higher-quality options.

Factor in additional costs like installation and maintenance. Sometimes DIY is tempting, but mistakes can lead to higher expenses down the road. A small error in cutting can lead to waste. It’s crucial to research installation techniques thoroughly. Overlooking this can impact both time and money.

Budgeting should include long-term considerations. Polycarbonate panels are generally durable, but not all are equal. Cheaper options could lead to frequent replacements. Ask yourself—will the lower initial cost save you money, or will it end up costing more over time? Always analyze your needs and plan accordingly.

Installation Techniques and Maintenance Tips for Durability

When installing polycarbonate panels, proper techniques are essential for longevity. Start with a solid frame to support the panels. Using screws designed for polycarbonate is crucial. These create a secure hold without cracking the material. Industry reports indicate that panels can last over 20 years with correct installation. However, improper techniques can lead to water leaks and structural damage.

Maintenance is equally important. Regularly clean the panels with mild soap and water to prevent buildup. Dust and debris can degrade the material over time. Reports suggest that neglecting maintenance can reduce durability by up to 30%. Keep an eye out for scratches or discoloration, as these can impact clarity and strength. Timely repairs are vital to extending the lifespan of your panels. For example, a small crack could quickly lead to larger issues if not addressed. Aim for excellence, but remember that even minor mistakes can become significant problems.

Related Posts

-

How to Choose Transparent Polycarbonate for Your Projects?

-

Top 7 Benefits of Using Opaque Polycarbonate in Modern Architectural Design

-

What are Solid Plastic Sheets? A Comprehensive Guide to Their Uses and Benefits

-

How to Choose the Best Polycarbonate Multiwall Panels for Your Project

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

Top Solid Plastic Sheets Uses Benefits and Buying Guide