How to Choose the Right Polycarbonate Multiwall Sheet for Your Project?

Choosing the right polycarbonate multiwall sheet can be a daunting task. Experts in the field often emphasize the importance of understanding your project needs. Jack Thompson, a leading architect in sustainable design, once stated, “Selecting the correct polycarbonate multiwall sheet can make or break your project.” His insight highlights the critical role these materials play in various applications.

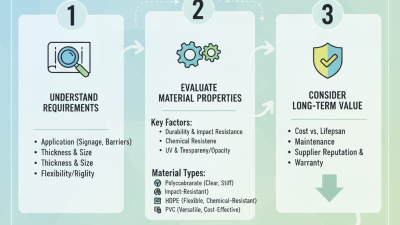

Polycarbonate multiwall sheets offer durability and versatility. They provide excellent insulation properties, making them ideal for greenhouses, skylights, and other structures. However, not all polycarbonate sheets are created equal. Some projects might suffer from poor light diffusion or inadequate thermal insulation. It’s essential to assess factors such as thickness, UV protection, and design before making a choice.

Consider your project's specific demands. A multiwall sheet's configuration can affect not just performance but also aesthetics. Many users overlook the importance of color and texture. Ensuring the right fit is critical. A wrong decision may lead to costly adjustments later. It's worth dedicating time to research and consult with experts to avoid pitfalls.

Understanding Polycarbonate Multiwall Sheets and Their Applications

Polycarbonate multiwall sheets are versatile materials used in many projects. They provide excellent thermal insulation, UV protection, and impact resistance. Many applications exist, from greenhouses to skylights. Understanding their unique properties can help you choose the best option.

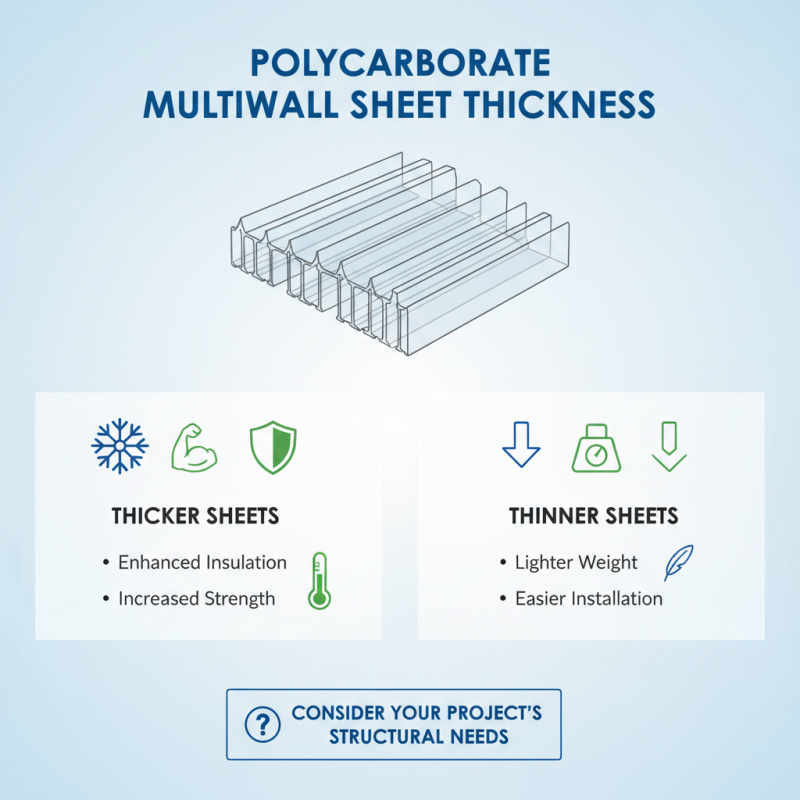

When selecting polycarbonate sheets, consider factors like thickness, number of walls, and whether they’re structured for specific environments. For example, thicker sheets often offer better insulation. Multiwall structures can enhance strength while reducing weight. Look for sheets designed for outdoor use to ensure longevity.

**Tips:** Always assess your project's specific needs. If you require light diffusion, opt for frosted sheets. For areas exposed to extreme conditions, consider additional UV coatings. Don't forget to measure dimensions accurately; cutting mistakes can be costly.

Polycarbonate Multiwall Sheets Applications and Thickness Preferences

Evaluating the Key Properties of Polycarbonate Multiwall Sheets

Choosing the right polycarbonate multiwall sheet involves understanding its key properties. One important property is thickness. Thicker sheets provide better insulation and strength. However, they can be heavier and more challenging to install. Consider your project's structural needs.

Another significant factor is UV resistance. This property ensures the longevity of the sheets. Not all sheets offer the same level of protection. Some may degrade faster under sunlight. Researching this aspect can save you future headaches.

Transparency is critical, too. Different multiwall sheets have varying levels of light transmission. This can affect the interior lighting of your space. Clear sheets allow maximum light, while tinted options offer privacy. Assess the ambiance you want to create. Balancing all these properties isn’t easy. It requires a thoughtful approach.

Factors to Consider When Choosing Thickness and Panel Configuration

When selecting polycarbonate multiwall sheets, thickness is crucial. Thicker panels generally provide better insulation and impact resistance. Industry studies indicate that sheets of 10mm thickness can reduce heat loss by up to 20% compared to thinner options. However, one should consider project-specific needs. For instance, a greenhouse might benefit from moderate thickness to allow optimal light penetration.

Panel configuration also plays a significant role. Different configurations, such as twin-wall or triple-wall designs, offer varying thermal performances. A report from the Polycarbonate Council shows that triple-wall panels can improve energy efficiency by up to 30%. This can be essential for structures requiring precise temperature control, like agricultural facilities.

Choosing the right combination is not always straightforward. Budget constraints may limit options. Balancing between thickness, configuration, and cost often leads to difficult decisions. Exploring various thicknesses can sometimes reveal that a slightly thinner sheet suffices for your needs, thus saving money. Addressing such trade-offs is essential when deciding on polycarbonate sheets for your project.

How to Choose the Right Polycarbonate Multiwall Sheet for Your Project? - Factors to Consider When Choosing Thickness and Panel Configuration

| Thickness (mm) | Panel Configuration | R-Value (insulation) | Light Transmission (%) | Weight (kg/m2) | Best Use Cases |

|---|---|---|---|---|---|

| 4 | 2-Wall | 1.4 | 82 | 5.0 | Greenhouses, sheds |

| 6 | 3-Wall | 1.8 | 80 | 7.0 | Skylights, carports |

| 8 | 5-Wall | 2.1 | 75 | 9.5 | Commercial buildings, thermal insulation |

| 10 | 6-Wall | 2.5 | 70 | 11.5 | Airport hangars, warehouses |

Comparing the Benefits of Different Multiwall Sheet Structures

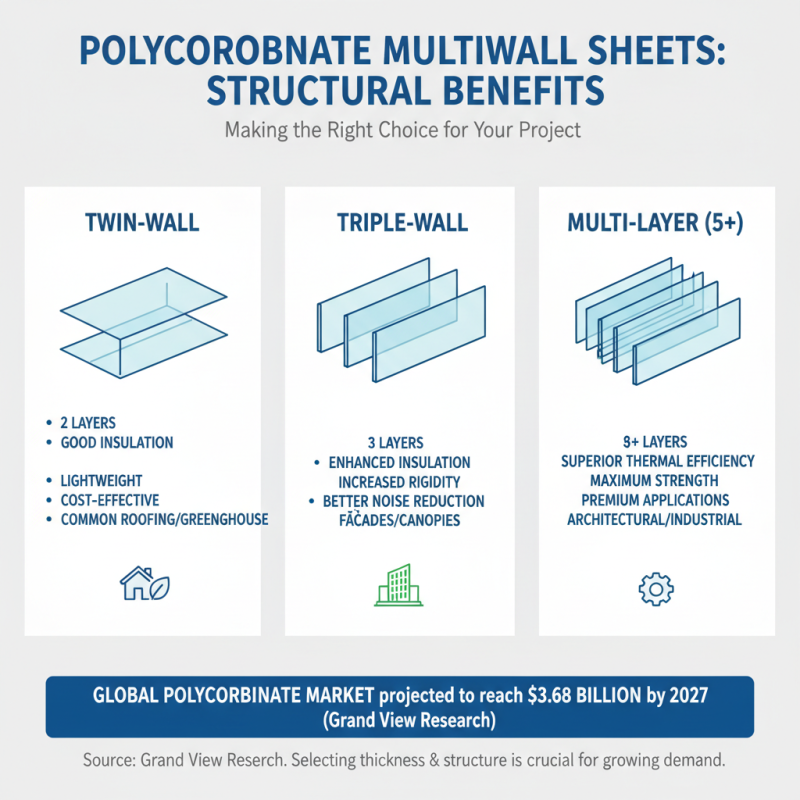

When evaluating polycarbonate multiwall sheets, it's crucial to compare the benefits of various structures. Multiwall sheets come with different configurations, such as twin-wall, triple-wall, and even more layers in some cases. According to a report from Grand View Research, the global polycarbonate market is expected to reach $3.68 billion by 2027. As the demand grows, selecting the right thickness and structure becomes challenging yet essential.

Twin-wall structures are lighter and more cost-effective. They are suitable for projects requiring good insulation without excessive weight. On the other hand, triple-wall sheets offer superior insulation and rigidity. They can enhance energy efficiency in greenhouses or commercial buildings. A study by Transparency Market Research indicates that energy efficiency is one of the top reasons for using multiwall sheets in construction. Yet, the choice isn’t always clear-cut; more insulation can lead to higher costs.

Some might assume that the more walls, the better the quality. However, increasing layers can also mean increased complexity in installation. Reflecting on this, it's important to consider the project's specific needs versus potential drawbacks. Balancing cost, weight, and insulation properties might involve trade-offs. Each project could reveal a unique set of challenges, prompting stakeholders to reflect on their choices carefully.

Tips for Proper Installation and Maintenance of Polycarbonate Sheets

When installing polycarbonate multiwall sheets, proper techniques are crucial for longevity. Ensure the sheets are cut with precision. Each edge must be sealed to prevent water ingress. Failing to do this could lead to moisture accumulation and potential damage. A study showed that improperly sealed sheets reduce lifespan by 40%.

Ventilation is another critical factor. Areas under the sheets need airflow to avoid condensation. This is especially true in humid climates. Aim for a minimum of 2 to 4 inches between the sheets and any solid surface. This allows for natural air circulation. Often, installers forget this step, leading to unexpected maintenance issues.

Regular maintenance can prevent costly repairs. Inspect for scratches and surface damage every season. Minor issues can often be fixed easily. An annual cleaning with mild soap and water keeps the sheets clear. Using abrasive cleaners may result in permanent marks. Always prioritize thoughtful installation and ongoing care to ensure durability.

Related Posts

-

How to Choose the Best Polycarbonate Multiwall Panels for Your Project

-

The Ultimate Guide to Polycarbonate Multiwall Sheets Benefits and Uses

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

2026 How to Choose Solid Plastic Sheets for Your Next Project?

-

2026 Top Polycarbonate Suppliers for Your Essential Needs?

-

Top 10 Benefits of Using Coloured Sheets for Your Home and Office