2025 How to Choose Clear Plastic Sheets for Maximum Durability and Versatility

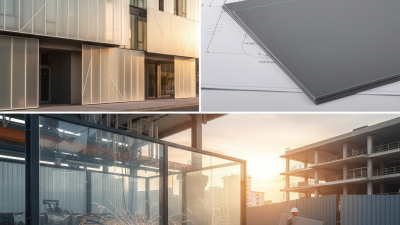

In the world of manufacturing and construction, the selection of materials is paramount to ensuring the longevity and functionality of a project. Clear plastic sheets have gained significant recognition for their versatility and durability, making them a preferred choice across various industries. According to a report by Transparency Market Research, the global polycarbonate sheet market is projected to reach USD 2.4 billion by 2026, reflecting the increased demand for high-quality materials that offer both clarity and resilience. The ability of clear plastic sheets to withstand harsh environmental conditions without compromising transparency is a key factor driving this growth.

As industries evolve, the need for materials that are not only cost-effective but also sustainable becomes ever more critical. Clear plastic sheets meet these demands by offering exceptional strength-to-weight ratios and a low environmental impact in comparison to traditional glass options. Moreover, their versatility allows for applications ranging from protective barriers in commercial spaces to customizable features in residential design. An insightful study from Grand View Research highlights that the rise in remodeling activities and the construction of green buildings are expected to further fuel the demand for such adaptable materials. Understanding how to choose the right clear plastic sheets is essential for maximizing their benefits and ensuring that projects can withstand the test of time.

Understanding Clear Plastic Sheets: Types and Features

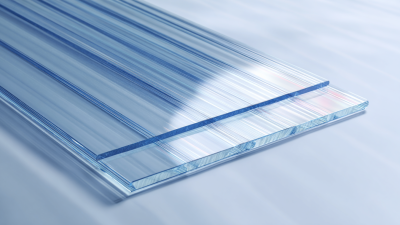

Clear plastic sheets are versatile materials that come in a variety of types, each suited for different applications. The most common types include acrylic, polycarbonate, and PVC. Acrylic sheets offer excellent clarity and are lightweight, making them perfect for display cases and signage. Polycarbonate, on the other hand, is known for its exceptional impact resistance, making it ideal for safety glazing and protective barriers. PVC sheets are more flexible and are often used in applications where chemical resistance is required.

When selecting clear plastic sheets, it’s crucial to consider their features, such as thickness, UV resistance, and temperature tolerance. Thicker sheets generally provide greater durability but may be heavier and less flexible. UV resistance is essential for outdoor applications to prevent yellowing and degradation from sunlight exposure. Additionally, knowing the temperature tolerance helps to ensure that the material will withstand environmental conditions without warping or breaking. With the right combination of type and features, clear plastic sheets can be effectively utilized in a wide range of projects while ensuring long-term performance.

Assessing Durability: Key Factors in Plastic Sheet Selection

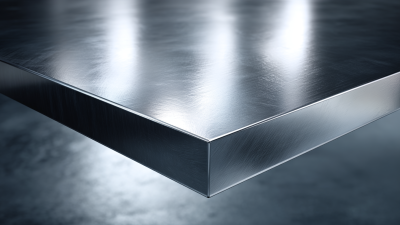

When selecting clear plastic sheets, assessing

durability is crucial for ensuring long-term performance

across various applications. The most significant factor influencing durability is the

material composition.

Polycarbonate and acrylic

are two popular choices, with polycarbonate offering unparalleled impact resistance, rated to withstand

up to 200 times stronger than glass. According to a report by the Plastics Industry Association,

polycarbonate sheets can endure extreme weather conditions, making them ideal for outdoor use.

Another key consideration is the thickness of the sheets. Research indicates that

thicker sheets not only provide better structural integrity but also better protection

against UV radiation, which can lead to discoloration and brittleness over time. The American Society

for Testing and Materials (ASTM) recommends using sheets that are at least

0.125 inches thick for applications requiring

maximum durability. Furthermore, an effective protective coating can enhance the lifespan of plastic sheets,

providing a barrier against environmental stressors. By prioritizing these factors—material choice,

thickness, and protective coatings—users can significantly improve the versatility and longevity of their

plastic sheet applications.

Exploring Versatility: Common Applications of Clear Plastic Sheets

Clear plastic sheets, particularly acrylic and polycarbonate varieties, have become staples in various industries due to their remarkable versatility and durability. These sheets are commonly used in applications ranging from signage and displays to protective barriers and structural components in construction. Their lightweight nature and resistance to UV rays and impact make them ideal for both indoor and outdoor use.

When considering how to choose the right clear plastic sheets, think about the specific requirements of your project. Acrylic sheets are a great option for applications requiring excellent transparency and rigidity, while polycarbonate sheets offer superior impact resistance, making them suitable for more demanding environments.

**Tips:** Always assess your project's environmental factors, such as exposure to sunlight or potential impacts. Additionally, consider the thickness of the sheet; thicker materials often provide enhanced durability. Lastly, check the temperature tolerance to ensure that the selected plastic can withstand the conditions of your application while maintaining its integrity.

Durability and Versatility of Clear Plastic Sheets in Various Applications

Maintenance Tips for Long-lasting Clear Plastic Sheets

When it comes to clear plastic sheets, proper maintenance plays a crucial role in extending their lifespan and ensuring optimal performance. By following some key maintenance tips, you can keep your sheets looking great and functioning effectively for years to come.

One important tip is to regularly clean your plastic sheets using a gentle soap solution and a soft cloth. Avoid using abrasive materials or harsh chemical cleaners, as these can scratch or damage the surface. Additionally, rinsing the sheets with water after cleaning will help remove any soap residue, preventing buildup that can cloud the material.

Another tip for long-lasting clear plastic sheets is to store them properly when not in use. Keep them in a cool, dry place away from direct sunlight to prevent warping and fading. It’s also wise to cover them with a protective layer, such as a soft blanket or cardboard, to avoid scratches and dust accumulation. By implementing these maintenance practices, you can enhance both the durability and versatility of your clear plastic sheets.

Comparison of Clear Plastic Sheets: Cost, Quality, and Performance

When selecting clear plastic sheets, understanding the cost, quality, and performance is crucial to achieving maximum durability and versatility. According to a report by the Plastics Industry Association, the average cost of polycarbonate sheets ranges from $2 to $8 per square foot, depending on thickness and treatment. Polycarbonate is particularly renowned for its impact resistance, boasting a strength up to 200 times that of glass, making it ideal for high-performance applications like safety glasses and greenhouse panels. Alternatively, acrylic sheets, which cost about $1.50 to $6 per square foot, offer exceptional clarity and UV resistance, but are less durable compared to polycarbonate.

Tips: When comparing options, consider how each type of plastic performs under specific environmental conditions. For example, if the sheets will be exposed to high temperatures, polycarbonate is often a better choice due to its thermal stability. Additionally, check for scratch-resistant coatings or treatments, as they can significantly extend the life of the product, especially in outdoor applications or environments where abrasion is likely.

Another point of comparison is the ease of fabrication. Reports indicate that acrylic sheets can be easily cut and shaped with standard tools, making them a preferred choice for DIY projects. Conversely, polycarbonate can require specialized tools for machining to avoid cracking. This distinction can affect labor costs and project timelines, making it an essential factor in decision-making.

Related Posts

-

How to Use Opaque Plastic Sheeting for Effective Light Blockage and Privacy

-

What are Solid Plastic Sheets? A Comprehensive Guide to Their Uses and Benefits

-

Top 10 Benefits of Using Transparent Sheets for Your DIY Projects

-

Top 7 Benefits of Using Opaque Polycarbonate in Modern Architectural Design

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

Top 10 Benefits of ABS Material in Manufacturing for Enhanced Durability and Cost Efficiency