Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

When considering materials for your next project, polycarbonate sheets stand out as a versatile and durable option. As renowned expert Dr. Emily Carter, a leading authority in polymer technology, states, "Polycarbonate sheets combine the best of strength, clarity, and lightweight design, making them ideal for a variety of applications." This powerful material has gained traction across multiple industries, from construction to signage, owing to its remarkable properties that often surpass those of traditional glass or acrylic alternatives.

Polycarbonate sheets offer a unique blend of benefits that cater to both functionality and aesthetics. Their exceptional impact resistance and UV protection ensure longevity in outdoor settings, while their optical clarity allows for natural light to filter through, enhancing the ambiance of any space. Whether you're embarking on a DIY project or planning a large-scale construction endeavor, understanding the advantages of polycarbonate sheets can significantly influence your material choice. As we delve deeper into the compelling reasons to choose polycarbonate sheets, we'll uncover how they can elevate your project while providing practical solutions to common challenges.

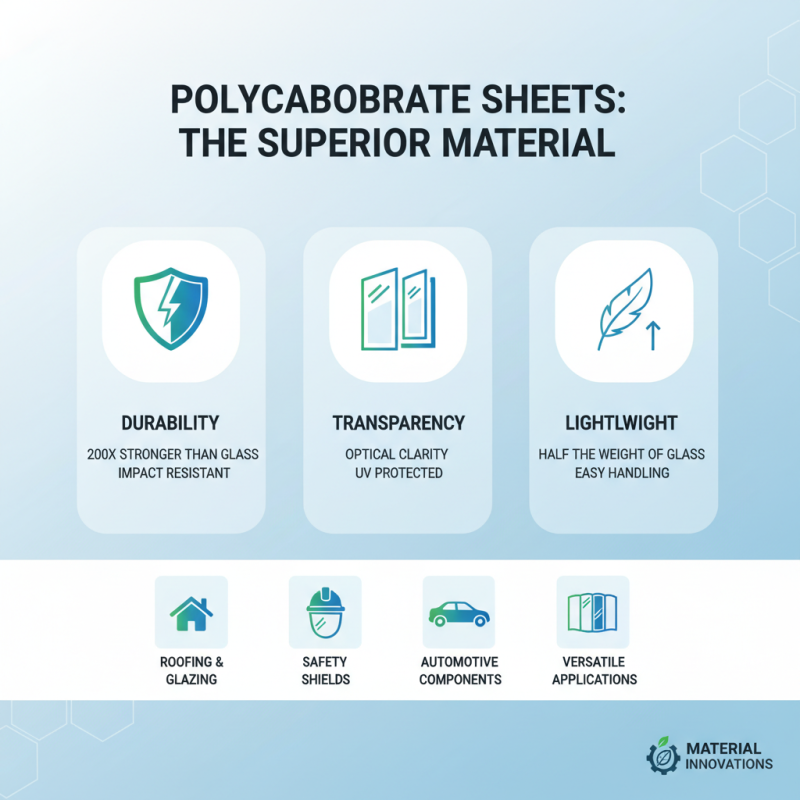

Understanding Polycarbonate Sheets: An Overview of Their Composition

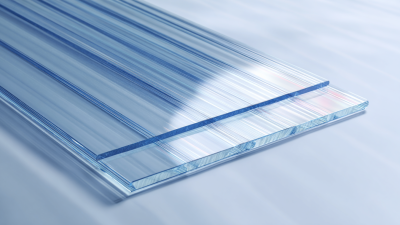

Polycarbonate sheets are a remarkable material that has gained popularity across various industries due to their superior properties. Composed primarily of polycarbonate resin, these sheets are known for their durability, transparency, and lightweight characteristics. Research indicates that polycarbonate can withstand significant impact, making it up to 200 times stronger than glass while being only half the weight. This unique combination of strength and lightweight design allows for versatile applications, from roofing and glazing to safety shields and automotive components.

Furthermore, the composition of polycarbonate sheets includes the incorporation of additives that enhance their performance. UV stabilizers are commonly added to prevent yellowing and degradation from prolonged exposure to sunlight, allowing for long-lasting clarity and strength. According to a report from the American Society for Testing and Materials (ASTM), polycarbonate sheets can maintain their optical clarity and structural integrity over an extensive range of temperatures, from -40°C to 120°C. This thermal stability, in conjunction with its impact resistance, makes polycarbonate sheets ideal for both indoor and outdoor applications, thus providing users with cost-effective and reliable solutions for their projects.

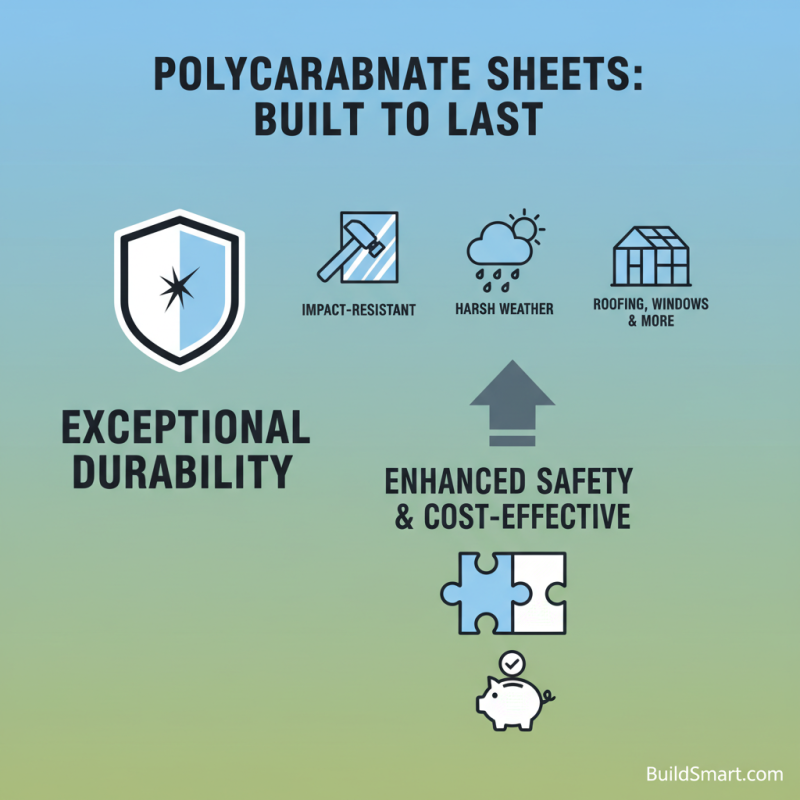

Key Benefits of Using Polycarbonate Sheets for Construction Projects

Polycarbonate sheets have become a popular choice for construction projects due to their numerous benefits. One key advantage is their exceptional durability. These sheets are highly resistant to impact and can withstand harsh weather conditions, making them ideal for roofing, windows, and even greenhouses. The strength of polycarbonate minimizes the risk of breakage, which is not only cost-effective but also enhances safety in various applications.

Another significant benefit is their lightweight nature. Polycarbonate sheets weigh less than glass, which simplifies handling and reduces transportation costs. Additionally, their ease of installation saves time and labor expenses on construction sites. This versatility allows for creative designs without compromising strength or safety.

**Tips: When working with polycarbonate sheets, consider using UV-protective coatings, especially for outdoor applications to prevent yellowing and maintain clarity. Also, ensure proper sealing at the edges to prevent moisture infiltration and optimize the lifespan of your installation.**

Furthermore, polycarbonate sheets offer excellent insulation properties, helping to regulate temperature and reduce energy costs. Their ability to transmit light while providing insulation makes them perfect for applications requiring natural lighting without sacrificing energy efficiency. This combination of strength, weight, and insulating capabilities makes polycarbonate sheets an outstanding choice for your next construction project.

Comparative Advantages: Polycarbonate Sheets vs. Other Materials

When considering materials for construction or design, polycarbonate sheets stand out due to their remarkable properties. Unlike glass, polycarbonate is virtually unbreakable, making it an ideal choice for applications that require durability. This impact resistance not only enhances safety but also reduces the risk of costly repairs or replacements. Furthermore, polycarbonate sheets are significantly lighter than glass, which simplifies transportation and installation. This weight advantage allows for greater flexibility in design, as structures can support larger spans without requiring extensive framing.

In comparison to traditional acrylic, polycarbonate sheets offer superior strength and thermal stability, making them suitable for environments with fluctuating temperatures. While acrylic may yellow over time when exposed to UV light, high-quality polycarbonate sheets maintain clarity and resistance to environmental degradation. Additionally, polycarbonate can be easily molded into various shapes, providing more creative possibilities for architects and designers. When it comes to insulation, polycarbonate performs remarkably well, offering better thermal efficiency than many other materials. As a result, polycarbonate not only fulfills aesthetic needs but also contributes to energy savings and enhances overall building performance.

Applications of Polycarbonate Sheets in Various Industries

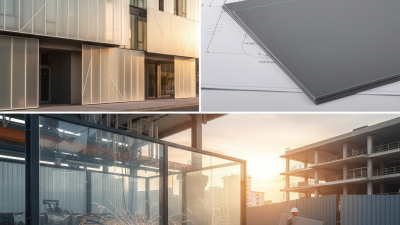

Polycarbonate sheets have emerged as a versatile material across various industries due to their remarkable physical properties. In the automotive sector, for instance, these sheets are utilized in manufacturing lightweight, impact-resistant components that enhance vehicle safety and fuel efficiency. Their ability to withstand harsh weather conditions makes them ideal for windshield applications, providing clear visibility without compromising structural integrity.

In the construction industry, polycarbonate sheets are increasingly favored for roofing and glazing solutions. Their high transparency allows natural light to illuminate interior spaces, reducing the need for artificial lighting during the day. Additionally, they offer excellent thermal insulation, contributing to energy efficiency in buildings. From skylights to facade panels, their aesthetic appeal combined with durability makes them an attractive choice for architects and builders alike.

Furthermore, polycarbonate sheets find application in the electronics sector, where they are used for manufacturing protective covers and housings. Their ability to resist high impact and extreme temperatures ensures the safety of sensitive electronic components. In the signage industry, polycarbonate sheets are employed for creating vibrant, weather-resistant displays that effectively communicate information in both commercial and public spaces. This wide range of applications highlights the adaptability of polycarbonate sheets in meeting diverse industry needs.

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits - Applications of Polycarbonate Sheets in Various Industries

| Industry | Application | Benefits | Thickness Options (mm) |

|---|---|---|---|

| Construction | Skylights | UV protection, energy efficiency | 4 - 25 |

| Automotive | Windows and Roofs | Lightweight, impact resistance | 1.5 - 10 |

| Electronics | Protective Covers | Chemical resistance, durability | 2 - 12 |

| Agriculture | Greenhouses | Insulation properties, light diffusion | 6 - 20 |

| Signage | Banners and Displays | Weather resistance, customizability | 2 - 15 |

Maintenance and Care Tips for Longevity of Polycarbonate Sheets

Maintaining polycarbonate sheets is crucial for ensuring their longevity and optimal performance. Regular cleaning is essential to prevent dust and debris buildup, which can obscure visibility and reduce light transmission. It is recommended to use a mild soap solution and a soft cloth or sponge for cleaning, avoiding abrasive materials that can scratch the surface. Additionally, rinsing the sheets with clean water after washing can help remove any soap residue, preserving their clarity.

Furthermore, it’s important to keep an eye on the sealing edges of the polycarbonate sheets. Over time, seals may degrade, leading to potential leaks or moisture buildup that could compromise structural integrity. Inspecting these areas periodically and replacing seals when necessary will help maintain the sheets' protective qualities. For outdoor installations, using UV-protective coatings can also extend the lifespan of polycarbonate sheets, shielding them from the harmful effects of sun exposure.

By following these maintenance tips, you can ensure that your polycarbonate sheets not only last longer but also perform at their best throughout their life cycle.

Related Posts

-

10 Best Solid Polycarbonate Sheets for Durability and Versatility in 2023

-

How to Choose the Best Polycarbonate Multiwall Panels for Your Project

-

What are Solid Plastic Sheets? A Comprehensive Guide to Their Uses and Benefits

-

Top Benefits of Using Coloured Plastic Sheets in 2025 for Your Projects

-

2025 Top Plastic Products Trends and Innovations Driving Sustainable Growth

-

2025 How to Choose Clear Plastic Sheets for Maximum Durability and Versatility