What is ABS Sheets and How Are They Used in Different Industries

ABS sheets, or Acrylonitrile Butadiene Styrene sheets, are a versatile and widely used material in various industries, ranging from automotive to construction. According to Dr. Emily Carter, a noted expert in polymer science, “ABS sheets provide an ideal combination of strength and flexibility, making them indispensable in modern manufacturing processes.” This unique material is known for its impact resistance, lightweight characteristics, and ease of fabrication, which all contribute to its increasing popularity across sectors.

In the automotive industry, ABS sheets are used for interior components, ensuring durability while maintaining aesthetic appeal. Furthermore, in construction, they serve as durable surfaces for both residential and commercial applications. As industries continue to evolve, the demand for innovative materials like ABS sheets is poised to grow even further, underscoring their importance in achieving efficiency and longevity in design and production. Understanding the myriad applications and benefits of ABS sheets can help businesses make informed decisions about material selection, ultimately leading to improved performance and cost-effectiveness in their respective fields.

What Are ABS Sheets? Composition and Properties Explained

ABS sheets, short for Acrylonitrile Butadiene Styrene sheets, are versatile thermoplastic materials widely used in various industries due to their excellent balance of strength, flexibility, and impact resistance. Composed of three monomers – acrylonitrile, butadiene, and styrene – ABS sheets exhibit impressive mechanical properties along with good thermal stability. These characteristics make them suitable for applications ranging from automotive components to electronic housings.

The unique composition of ABS sheets contributes to their desirable qualities. Acrylonitrile imparts chemical resistance and rigidity, while butadiene enhances toughness and impact strength. Styrene provides ease of processing and improves surface finish. As a result, ABS sheets can be fabricated easily using methods like injection molding and thermoforming, allowing for intricate designs and various thicknesses. Industries, including consumer goods, construction, and furniture, leverage these traits for producing durable and aesthetically pleasing products.

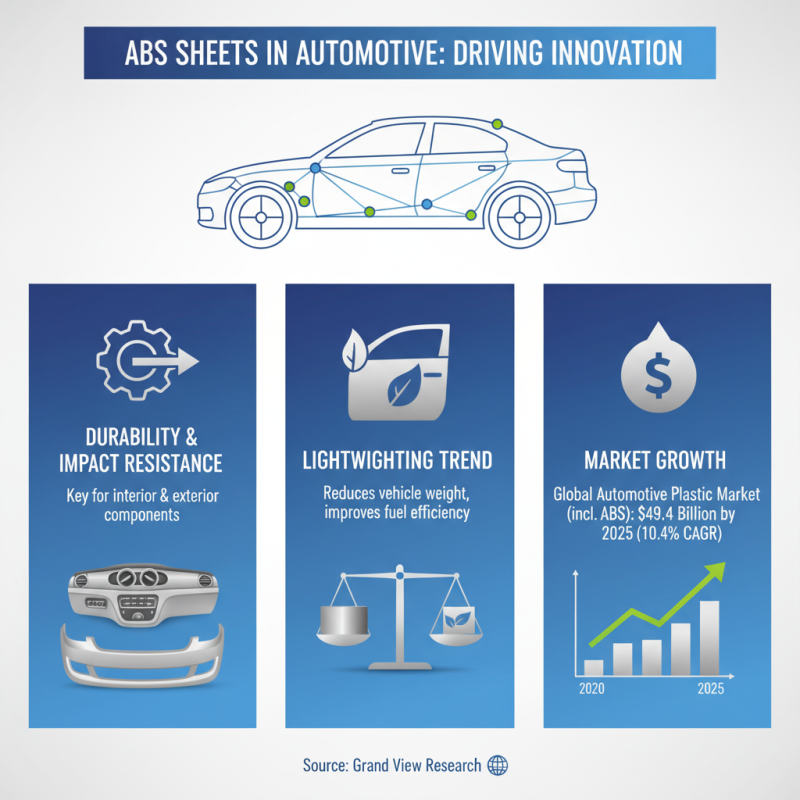

Applications of ABS Sheets in the Automotive Industry and Market Data

ABS sheets, known for their excellent durability and impact resistance, have become increasingly integral to the automotive industry. The automotive sector leverages ABS sheets not only for their functional properties but also for their aesthetic appeal. According to a report by Grand View Research, the global automotive plastic market, which includes materials like ABS, is expected to reach a value of USD 49.4 billion by 2025, growing at a CAGR of 10.4%. This growth indicates a substantial shift towards lightweight materials, a trend that ABS sheets fully support due to their lower weight compared to traditional materials.

In automotive applications, ABS sheets are utilized for various components such as dashboards, interior panels, and wheel covers. Their ability to withstand extreme temperatures and resist chemical exposure makes them an ideal choice for exterior parts that require durability. Additionally, ABS sheets can be easily molded and painted, allowing for innovative designs that enhance vehicle aesthetics. A study by Mordor Intelligence highlights that the automotive segment accounted for over 30% of the total demand for ABS sheets in 2022, reflecting a significant reliance on this material for both manufacturing and assembly processes in vehicle production. This trend underscores the critical role ABS sheets play in meeting the automotive industry's demands for safety, performance, and design flexibility.

How ABS Sheets Are Used in Electronics: Trends and Innovations

ABS sheets, known for their versatility and durability, are increasingly finding applications in the electronics industry. Their unique combination of lightweight properties, impact resistance, and excellent insulation capabilities makes them ideal for a variety of electronic products. From enclosures and housings for computers and consumer electronics to parts in telecommunication devices, ABS sheets offer a reliable solution that meets the stringent requirements of the sector. Innovations in ABS manufacturing processes have led to sheets that can be tailored for specific electrical characteristics, enhancing performance in high-tech devices.

One notable trend in the electronics sector is the shift toward sustainable practices, and ABS sheets are evolving to address this demand. Recent developments in bio-based and recycled ABS materials are paving the way for greener electronics manufacturing. These environmentally friendly options not only reduce the carbon footprint but also maintain the advantageous properties of traditional ABS, allowing manufacturers to adhere to sustainability goals without compromising on quality. As technology advances, the integration of ABS sheets in smart devices and IoT applications is expected to grow, showcasing their essential role in shaping the future of electronics.

ABS Sheets in Construction: Benefits, Applications, and Growth Statistics

ABS (Acrylonitrile Butadiene Styrene) sheets have gained significant traction in the construction industry due to their unique blend of properties that cater to diverse applications. One of the primary benefits of ABS sheets is their high impact resistance paired with a lightweight nature, making them ideal for use in building components such as wall panels, roofing, and facades. Their ability to withstand extreme temperatures and environmental conditions also contributes to their durability, further appealing to architects and builders looking for reliable materials.

Moreover, the versatility of ABS sheets lends themselves to various applications beyond mere structural components. They can be effectively utilized for insulation, soundproofing, and even aesthetic finishes, allowing for innovative designs in both residential and commercial construction projects. The increasing demand for sustainable and cost-effective materials has led to a marked growth in the production and adoption of ABS sheets, with statistics showing a steady rise in market usage across several construction sectors. As eco-friendly construction practices continue to gain momentum, ABS sheets are poised to remain a vital component in modern building projects.

Sustainability and Recycling of ABS Sheets in Various Sectors

ABS sheets, or Acrylonitrile Butadiene Styrene sheets, are widely recognized for their excellent durability and impact resistance. In addition to their diverse applications across industries like automotive, electronics, and construction, the focus on sustainability and recycling of ABS sheets has gained traction in recent years. Various sectors are actively seeking ways to minimize environmental impact, and this has led to innovative recycling practices and the use of reclaimed materials.

In the automotive industry, for example, efforts are being made to recycle ABS sheets from end-of-life vehicles. By reclaiming these materials, manufacturers can reduce the demand for virgin plastics and lower their carbon footprint. Similarly, in the electronics sector, the recycling of ABS components from old electronics contributes to a circular economy, where materials are continuously reused, thus minimizing waste and promoting sustainability.

Moreover, the construction industry is exploring the use of recycled ABS sheets for applications like interior design and building materials. By incorporating recycled content into new products, companies not only decrease their reliance on new resources but also enhance their sustainability profiles. Overall, the movement towards recycling and sustainable use of ABS sheets is shaping a more environmentally responsible future across various industries.

Related Posts

-

Why Choose Polycarbonate Sheets for Your Next Project and Their Benefits

-

The Ultimate Guide to Choosing the Best Transparent Sheet in 2025

-

Top Benefits of Using Polycarbonate Sheets for Your Home and Projects

-

How to Choose the Best Polycarbonate Multiwall Panels for Your Project

-

Top 10 Benefits of Using Transparent Sheets for Your DIY Projects

-

2025 Top 10 Clear Plastic Innovations Transforming Everyday Life